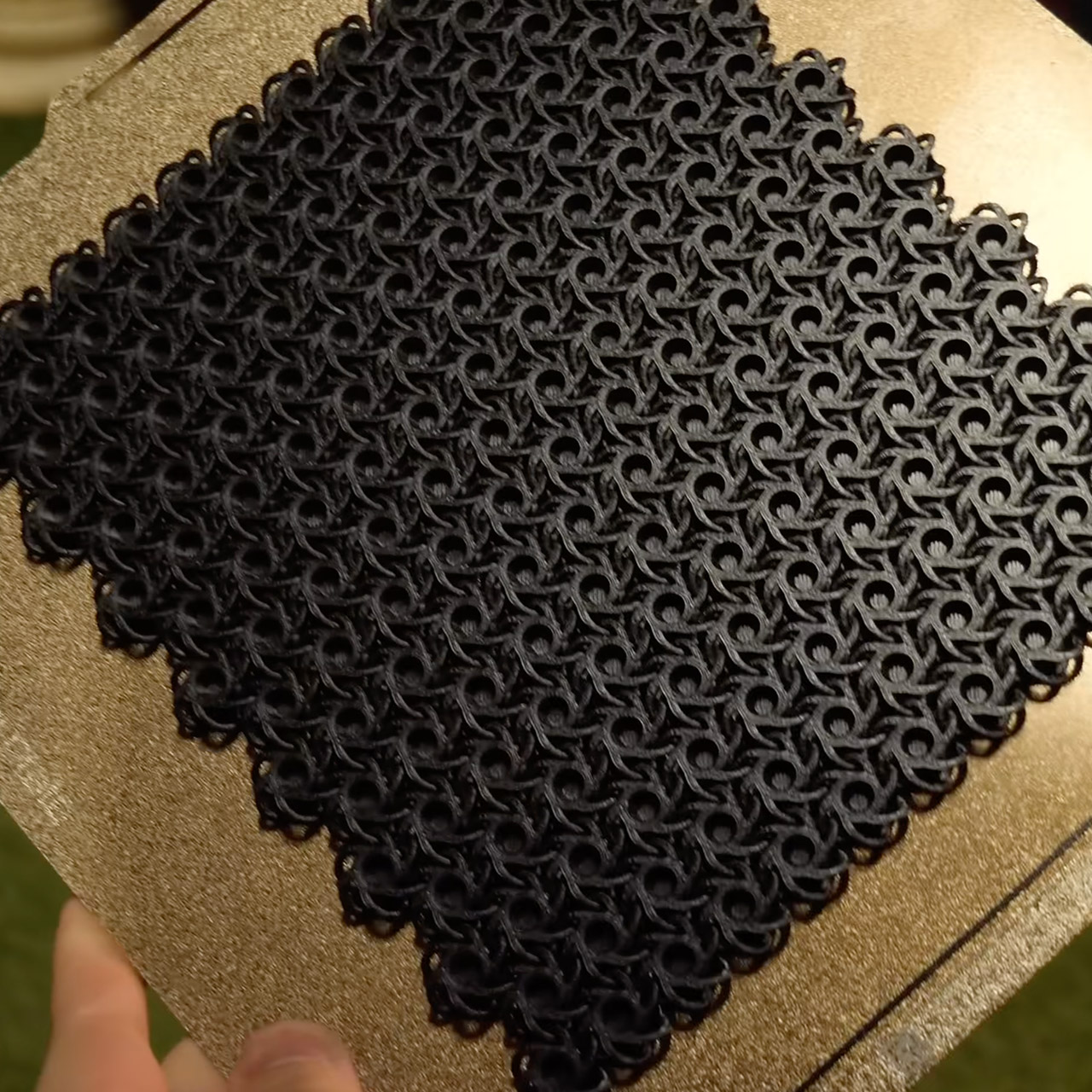

A single bed on a Bambu Lab 3D printer whirs away for hours, layer by layer, building up a strong PLA filament mat, strand by strand. When the platform has cooled down, the interlocking rings lift loose, revealing a flexible mat of plastic chainmail ready to be draped over a test dummy. The guys over at Screen Tested wanted to know if you could genuinely make decent armor on one of these fancy home 3D printers – could it resist real-world violence?

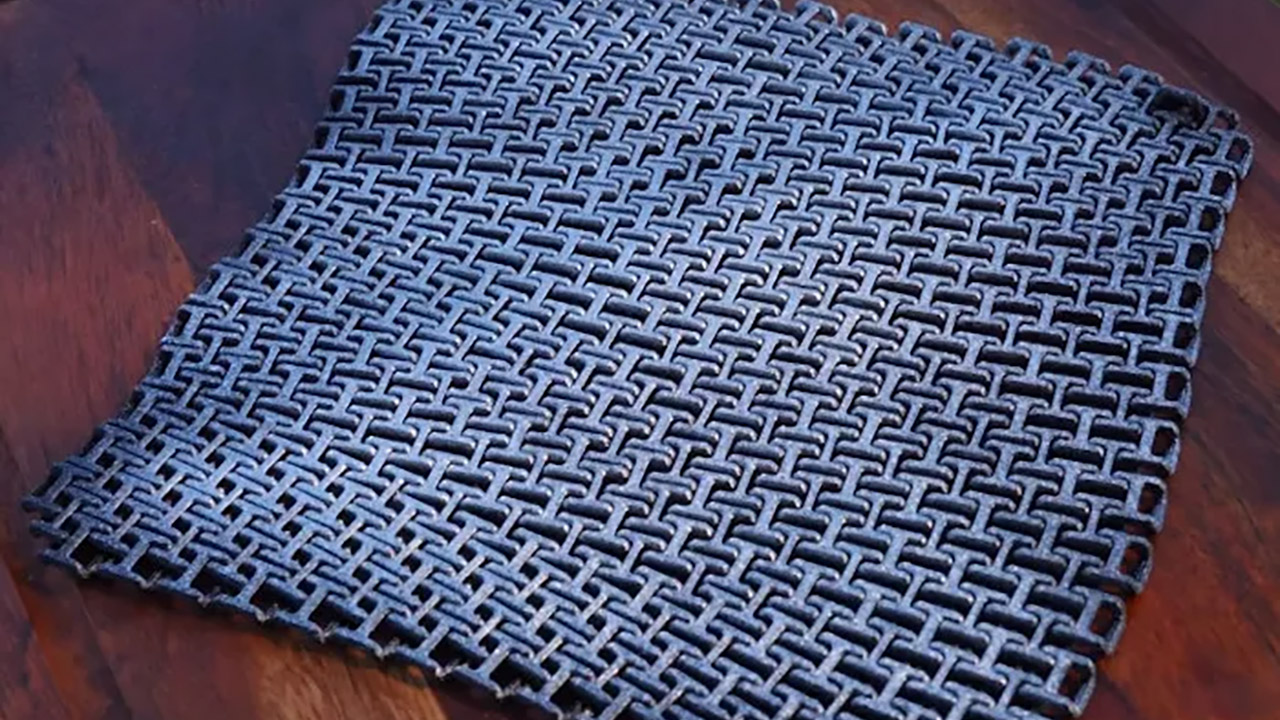

The design is a nice bit of work from MakerWorld, courtesy of user ZeroAlligator who came up with the PipeLink Chainmail Fabric thing. Each ring is only a few millimeters across and was printed flat in an H-pattern that just clicks into place as the nozzle moves back and forth. PLA is the material of choice here – its a tougher variety of the ordinary stuff you get in rolls of filament. Not a lot of infill is needed – enough to keep the shape but not so much that it gets too heavy or cumbersome – and a whole printer bed can churn out a torso-sized panel at one go.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000...

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make...

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,...

First up, a pair of scissors get put through their paces – the blades get wedged in between the rings, they spread a bit and then that’s it, they give up. No real damage is done to the gambeson underneath – a heavy quilted jacket. Then a screwdriver is used, really digging in with both hands. The tip gets snagged in the plastic loops and just gives up too. The links do bend a bit but they don’t snap. And that’s without the cushioning to boot.

A blunt longsword gets used next, and the thrusts all concentrate the force on a single spot. The sword pokes through a single link and gets stuck in the gambeson. But slashes – that’s a different story. The sword can get under the rings but it can’t really get a good grip – the edge just slides off and leaves a few scuff marks in the paint. Repeated cuts do bend a few links out of shape but they don’t snap – the plastic just absorbs the impact and springs back into place.

Now an 80-pound recurve bow gets put to work at 10 paces. The first arrow just goes straight through the mail and buries itself halfway into the gambeson before coming to rest just short of the dummy’s core. Broadheads come next – sharper and wider and meant to cause damage. They make bigger holes, shred a few ring clusters and embed themselves deep into the padding. Well, you see, chain mail – whether its steel or plastic – has always had a bit of trouble with arrows, and this version is no exception.

The gambeson is doing a useful job here, dispersing impact and catching stray points and converting what would have been stabs into bruises. Without it, even a screwdriver might have managed to draw some blood. And when you combine it with these plastic links, the combination is pretty good at beating bare skin in a low-speed showdown.

But thrusting weapons have found a chink in the armor – a keen sword tip, a bodkin arrow or an ice pick all manage to find the gaps. Real steel chainmail is the same – arrows and thrusts have been taking it down for generations. It’s just that this printed version doesn’t hold up as long before it gives way.

Tough PLA is pretty good for a day or so of hammering, but the lifespan is still a bit of a mystery. If you leave it in a hot car or a damp closet for a year or two it might start to get brittle. Steel mail rusts and plastic breaks – neither is going to last forever without a bit of TLC.

[Source]