Toast, a YouTuber who turns crazy ideas into real gadgets, decided to master one of the most complex machines in music. He wanted a piano that could be printed at home with a normal 3D printer. No strings or heavy wood frames – just layers of molten plastic that form keys, hammers and resonant tubes. The end result plays actual notes, fits on a desk and doesn’t cost much more than a few rubber bands.

Pianos require precision because the music comes from hammers striking taut steel strings. When you press a key, a system of levers propels the hammer forward and then allows it to rebound instantly and reset for the next strike. If you leave the hammer against the string, the note will end with a thud. Toast researched this action for months before taking the plunge. He replaced the strings with hollow plastic tubes. When you hit a tube the vibration remains even if the hammer is resting against it. This simple change eliminated the need for centuries old escape mechanisms.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000...

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make...

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,...

The tubes became the instrument’s heart and Toast used fundamental acoustics formulas to calculate the lengths. For an open-closed tube the length is one-quarter the wavelength of the desired note. Middle C at 523 hz requires a tube about 16cm long. He chose the C5 octave because higher pitches result in shorter tubes that can fit on a 25cm print bed. Tubes with both ends open would be twice as long and low notes would be out of reach for most printers.

Early versions had thick walls and heavy caps and sounded like tapping a plastic cup. Toast printed thousands of versions and reduced the wall thickness to 0.8mm while keeping the structural ribs for strength. Thin walls vibrate easily and produce clearer tones. He experimented with frequencies using a phone app and tweaked each tube until the pitch was close enough to piano notes to be melodic.

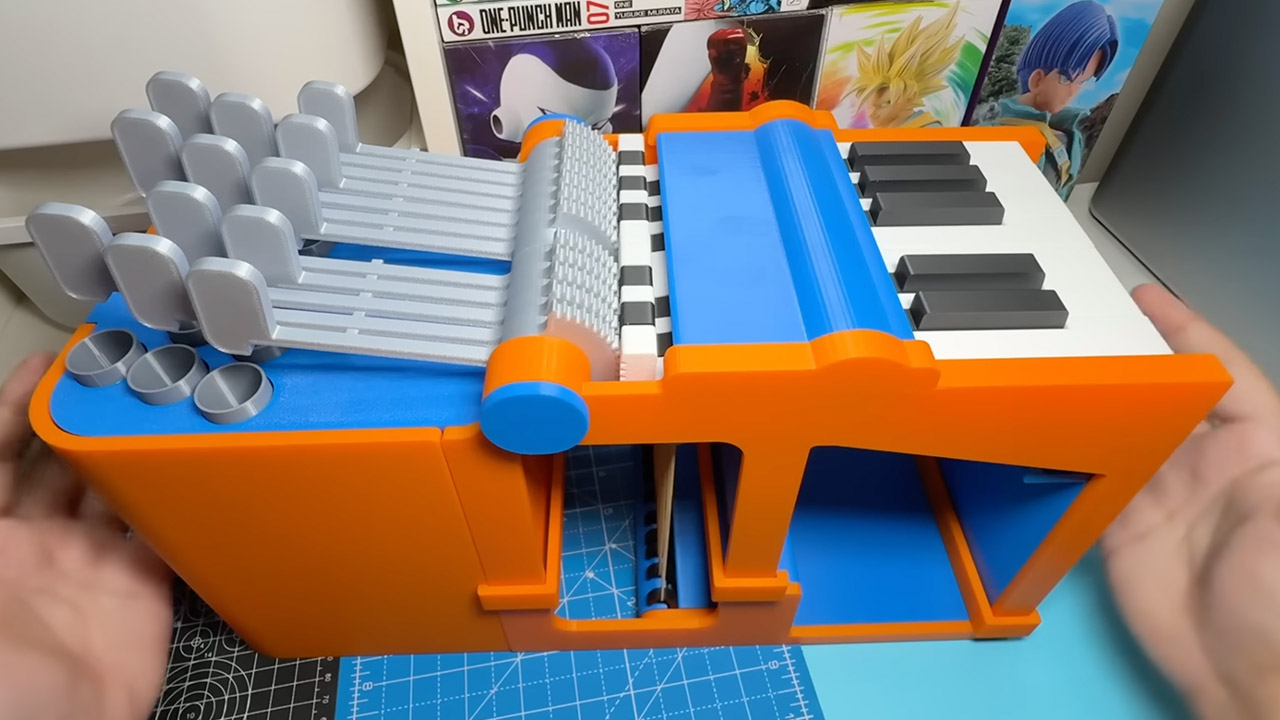

Keys attach to hammers by a simple pivot, and pressing down rotates the key 5 degrees, dropping the hammer onto the tube below. Release, and a rubber band secures everything back together. Spacers prevent hammers from grinding against adjacent keys during fast play. Early versions required 10 degrees of motion, which was excessive for flowing chords. By reducing the angle, the volume remained constant while the activity became more dynamic.

Toast redesigned the hammer mounts to feature sliding teeth, which took a long time to perfect and required hours of fussing with alignment when assembling. To set the drop hammers upright, insert a spacer at the desired angle and secure with end caps. As it happens, the entire octave (7 white keys and 5 blacks) just clips together in minutes. A dab of double-sided foam tape connects the key contacts, eliminating the unpleasant plastic clacks that drowned out your music in previous iterations.

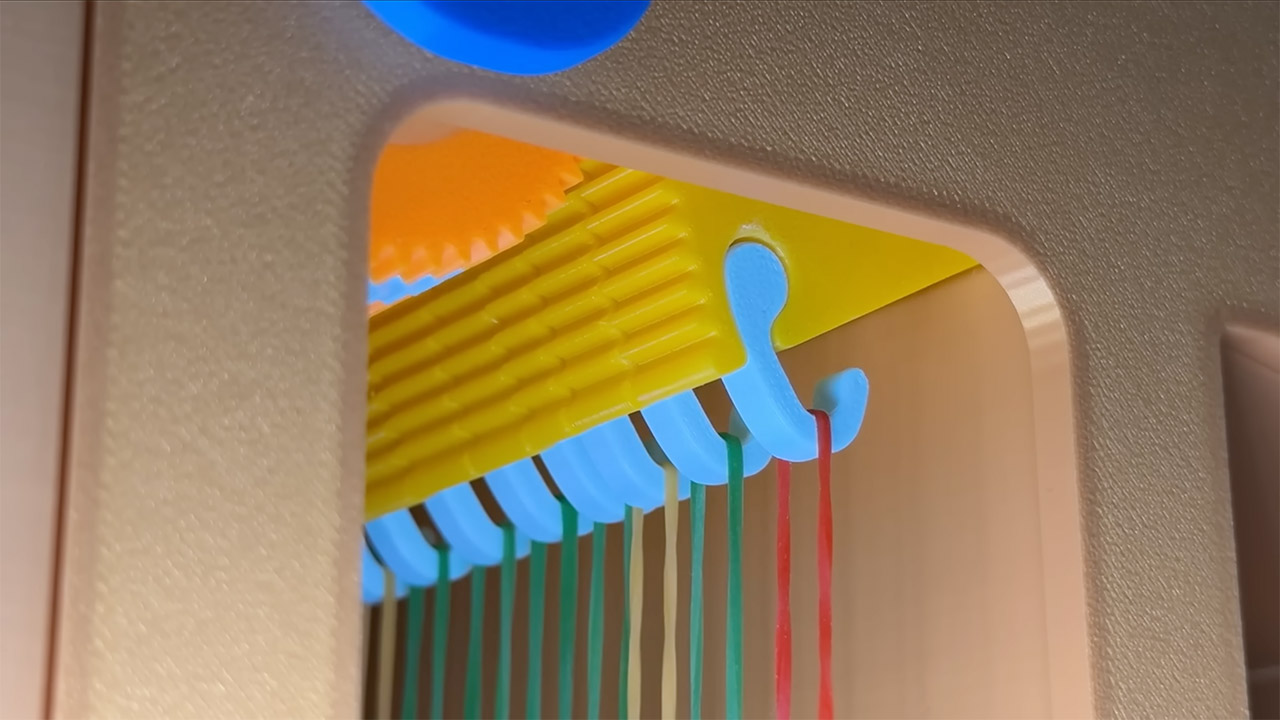

The finished piano spans one octave, with the tubes dropping in a staggered cascade, starting small on the right side and gradually increasing in size as they proceed to the left. This layout maximizes resonance while being as neat as possible. The hammers just dangle there overhead, resembling small pendulums. Print time for a mid-range printer using standard PLA is approximately 40 hours. The files also include detailed instructions, and you can customize settings such as layer height and infill values to meet your specific requirements.

[Source]