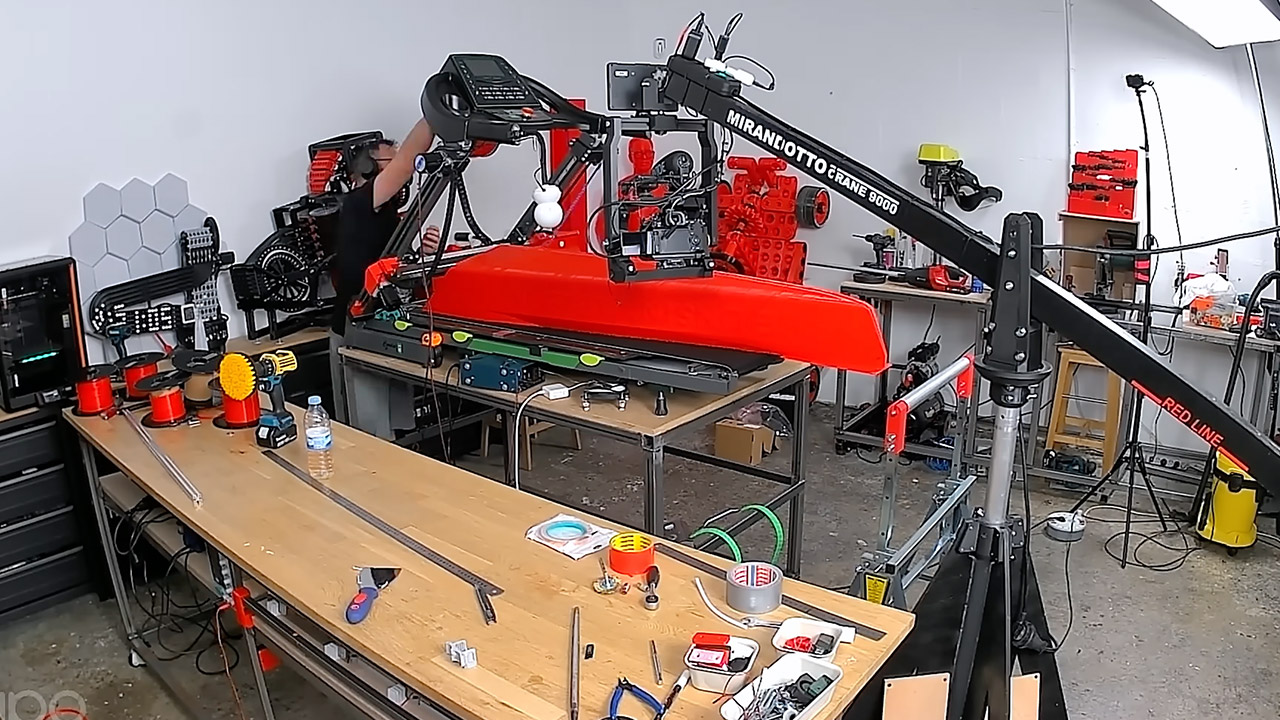

Ivan Miranda’s latest project—a full sized kayak printed in under 24 hours—takes additive manufacturing to new heights. Using a custom built 3D printer with a treadmill as the print bed, he aimed to print a functional watercraft faster than most people can assemble a piece of IKEA furniture.

Miranda’s custom machine uses the moving belt as an infinite Y-axis, perfect for printing long and slender objects like a kayak. His initial attempt to print a kayak took seven days. To cut that time in half, he rebuilt his setup, emphasizing speed without losing structural strength. The treadmill printer, which was already a work of DIY genius, required considerable modifications to fulfill the 24-hour deadline. This required updating the extruder, which melts and deposits plastic filament.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000...

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make...

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,...

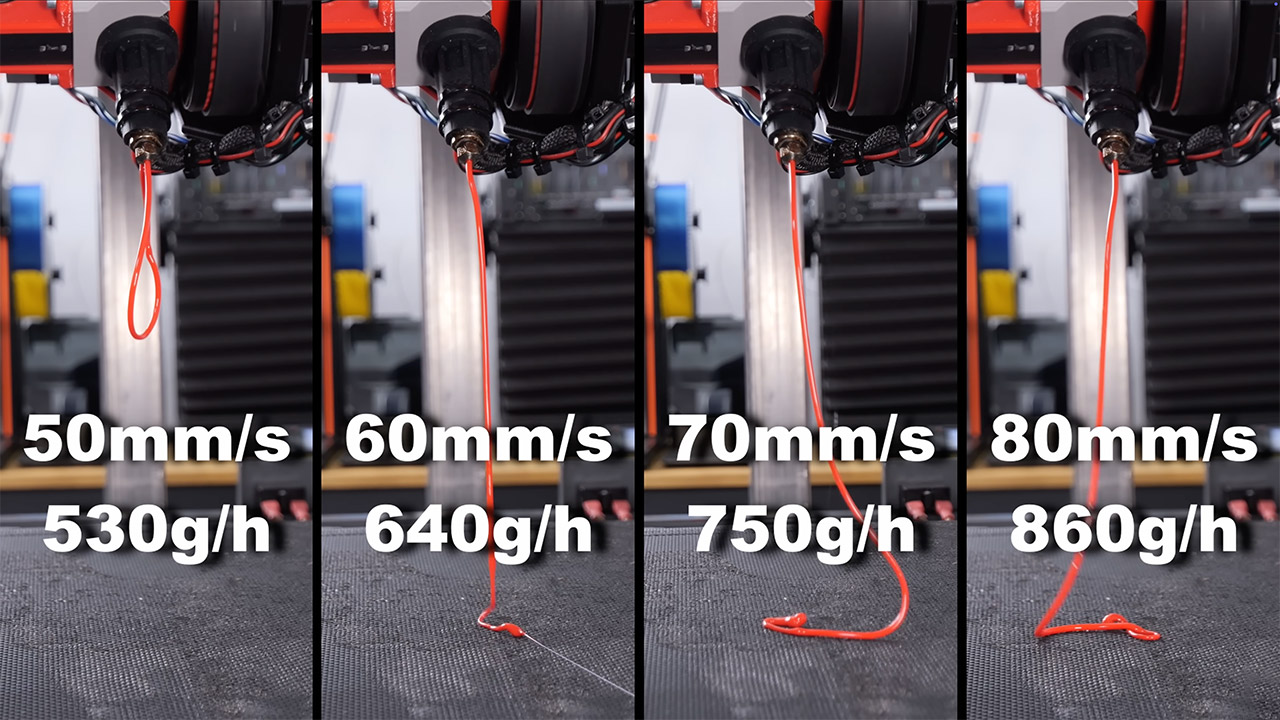

How so? Redesigning the extruder to create over 800 grams of plastic per hour, nearly double his previous output. This involved changing the standard 1mm nozzle with a bigger 1.8mm one, resulting in thicker and faster layers. But speed introduced new challenges, especially heat management. Printing at that pace generates a lot of thermal energy and the plastic needs to cool down fast to maintain structural integrity. His initial cooling fan couldn’t keep up, so two powerful fans were installed to solidify each layer before the next one was laid down. He also switched to heat-set inserts for easier assembly and maintenance.

Miranda used vase mode to speed things up, a 3D printing technique that creates a continuous spiral of material. This required a workaround: he added a cut at the base of the kayak, forcing the printer to print two walls around the entire structure, adding strength without breaking the continuous extrusion. Features like the seat and handle holes were integrated to maintain the flow, but gaps in the design relied on the molten plastic to fuse naturally during printing. The result was a sleek kayak printed in a single 20 hour and 51 minute session, with Miranda swapping out 2kg filament spools every 4.5 hours.

After printing, the kayak needed some finishing touches to be water ready. Miranda sanded down imperfections and used a 3D pen to fill small holes. To make it buoyant, he filled the bow and stern with foam to prevent it from breaking apart. A coat of epoxy sealed the hull to address the inevitable leaks of a 3D printed object. He also added handles and camera mounts and it was a functional if experimental vessel. The final weight was around 19kg and used around 19 spools of PLA filament at a cost of $190. For a custom kayak that’s a bargain but the real cost was in the hours and sleepless nights.

Miranda hauled it to the shore using a modified bike cart, and once in the water it floated – barely. Its narrow design, limited by the printer’s belt width, made it unstable especially in choppy waves. Miranda struggled to get in the cockpit, burning his feet on the hot surface and later getting a minor cut from the sharp edges. Water seeped in easily without a cover and the kayak tipped when not aligned perfectly with the waves. After multiple attempts, including a platform launch to avoid beach waves, Miranda admitted it wasn’t ocean ready. It’s a kayak for calm waters more so than rough seas.

[Source]