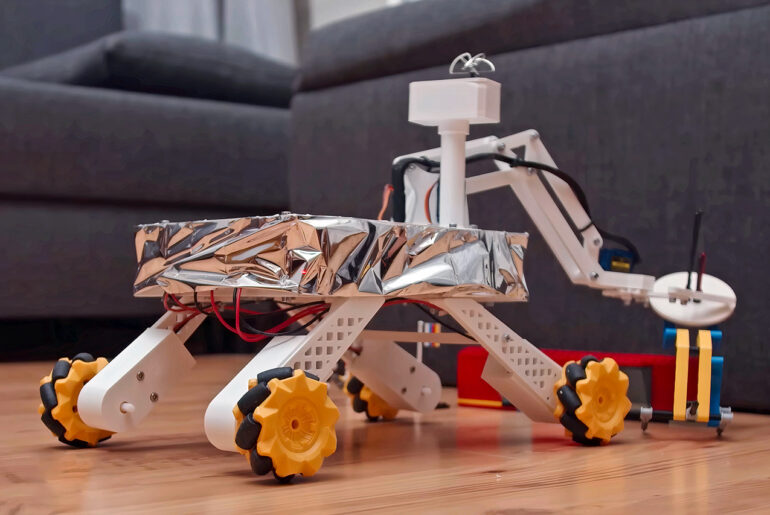

Inventor Nikoddem Bartnik has been fascinated by the Perseverance Mars Rover, so he decided to build a miniature version using Raspberry Pi and 3D-printed parts. At the heart of the rover is a Raspberry Pico W, which allows him to control it over Wi-Fi and a simple Python script. To operate the micro servo motors, a 50Hz PWM signal is used, while the DC motors required L298N drivers.

An FPV camera system didn’t cause too many issues, but needed a custom PCB made with a cheap CNC machine. Sure, this rover most likely would not survive in the actual Mars environment, but from the beginning, the goal was to educate and inspire rather than source pricey materials. What’s next? Nikodem is testing the Pico RP2040 chip and wants to eventually take long exposures of deep sky objects with a camera by compensating the movement of Earth.

- REMOVABLE BUILD SURFACE PLATE: Provide all-round protection to your 3D printer build plate and ensure consistent temperature throughout the build...

- SAFE POWER SUPPLY: Ender 3 Pro comes with a branded power supply, protecting your printer from unexpected power surges, that can heat the hot bed to...

- RESUME PRINT FUNCTION: Ender 3 Pro can resume printing from the last recorded extruder position after suffering unexpected power outages.

All parts were designed in such a way that you can print them on the most popular FDM 3D printers and you don’t need a huge build plate. The bottom plate was machined on my DIY CNC machine. The principle of how it works is very simple; designing and 3D printing it is not,” said Nikod.