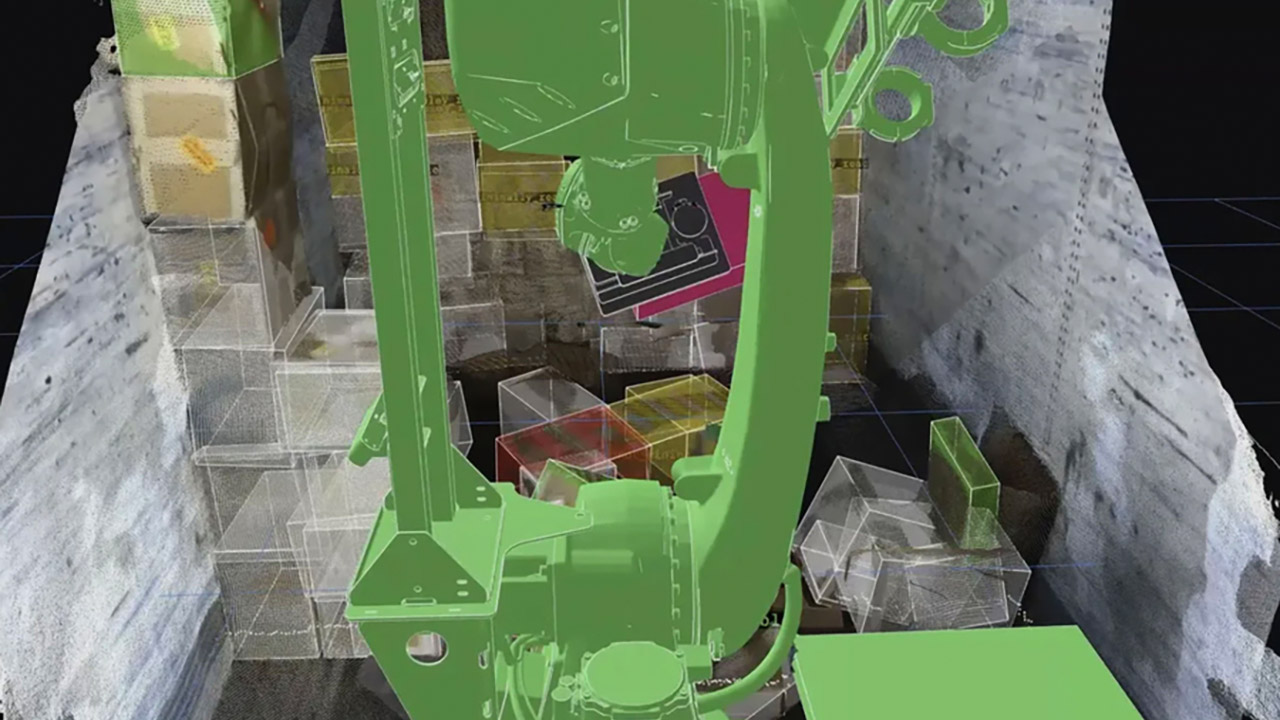

A single robotic arm bursts into action inside a pretty dim trucker trailer, its suction pad latching onto a cardboard box almost as smoothly as a pro would. There’s no fumbling around or dropping loads, which is a solid sign of years of fine-tuning. Pickle Robot Co is led by a group of MIT grads who have spent years honing this routine so that machines can perform it with precision.

AJ Meyer, Ariana Eisenstein, and Dan Paluska started the business in 2018 aiming to tackle one of the toughest jobs in logistics: unloading trucks and shipping containers stuffed with merchandise. Nowadays, with 130 people pushing the boundaries in Charlestown, Massachusetts, they’ve come up with a system to do just that, and it’s already hauling real weight in places like big apparel distribution facilities.

- Iconic LEGO Collection - The LEGO Speed Champions collection is full of iconic toy car models, including the Pagani Utopia (76915) and Porsche 963...

- LEGO Ferrari Collectible - Features a LEGO Speed Champions collectible model car replica of the Ferrari 812 Competizione plus a driver minifigure with...

- Race Driver Minifigure - The set includes a LEGO race driver minifigure to be placed behind the wheel of the race car toy for superfast action on the...

Pickle started out small – prototyping in garages and labs but the focus remained on getting a grip on the warehouse floor. Those early days were all about endless testing & experimenting with off-the-shelf hardware such as arms from KUKA, an industrial robotics old hand. Everything else was made up, from steel frames to keep the robot steady to cameras to scan the complete mess inside a trailer to sensors to map every inch & software to tie it all together. It costs roughly $30 000 for the arm on its own but the whole shebang – the whole kit – includes conveyors, mounts and the code to stack it all into existing operations seamlessly. Big customers like UPS & Yusen Logistics no longer pick up prototypes; instead they deploy these robots to mow through mountains of boxes day in day out.

The robot starts by working inside a trailer stacked to the brim with 800 to 1,200 cases. It rolls along on a mobile base, adjusts itself and gets the cameras transmitting data to the onboard computers. Machine vision software spots the next box based on its shape, size and position on the pile. The arm then extends, rotates if needs be and presses a pneumatic suction cup on any flat surface ( side, top or edge). Boxes come in all shapes & sizes from tiny 5-inch cubes to gigantic 24 by 30 inch flats, each weighing a max of 50 pounds. Once grabbed ,the arm raises up with ease, dodges tight spots near walls or ceilings before depositing the load onto a conveyor belt that feeds straight into the warehouse.

In this line of work, speed is, of course, critical because how effectively the system operates is totally dependent on what you’re moving (smaller boxes stack up much tighter than larger ones, for example), and that works out to anything from 400 to 1,500 cases per hour. When expressed in pounds, that sounds like a lot: 75,000 pounds of merchandise in a single shift with no breaks. One of these units began operations at Randa Apparel’s fulfillment center in mid-October 2025, and it has already unloaded more than 1.5 million pounds. Pilots in the steamy California warehouses, where temperatures climbed to 130 degrees Fahrenheit, demonstrated that they were all than capable of dealing with such heat, but most people would flee for the shade if it became that hot. Warehouse managers are already noticing less dock delays; formerly, cars would sit idle for hours while the crew rested.

The brains behind this operation are powered by generative AI that has been fine-tuned using existing models. This means it can learn new tricks quickly and become more effective. After only a few runs, it begins to adapt to every new arrangement that comes its way, instantly changing the most effective pathways to shave critical seconds off each pick. Its smaller learning algorithms handle navigation, which includes avoiding obstacles in new situations. It improves each time as it draws on a larger library of real-world data. Pickle also has a mechanism for picking parts from reputable vendors, which reduces costs while increasing output. This summer, development on a new edition begins, with the promise of even tighter integration with warehouse workflow.

[Source]