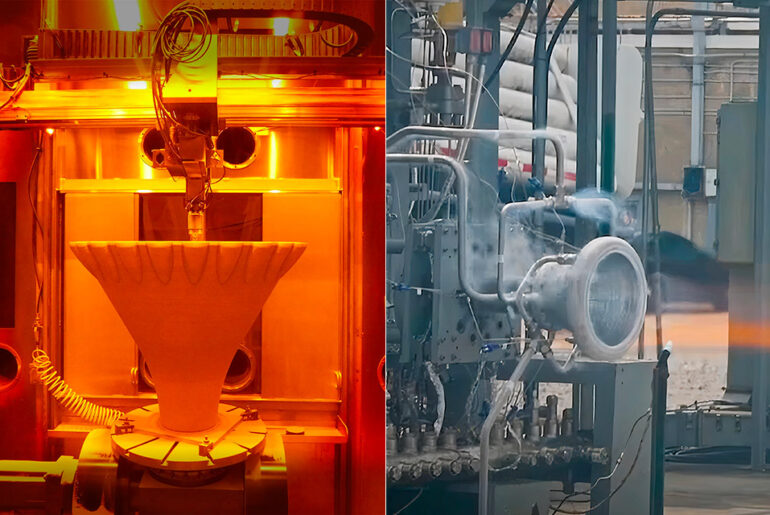

You’ve seen NASA’s 3D-printed rotating detonation rocket engine, now check out their RAMFIRE rocket nozzle manufactured using a similar process. RAMFIRE is lighter than conventional nozzles and could one day be used for deep space missions with heavier payloads.

NASA’s Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) project basically focuses on advancing lightweight, additively manufactured aluminum rocket nozzles. Each one is designed with small internal channels capable of keeping the nozzle cool enough to prevent melting. Rather than have a thousand individually joined parts, RAMFIRE is built as a single piece, thus significantly reducing manufacturing time.

- 1.Easy Assembly: Compared to Ender 3 V2, this Ender 3 V2 Neo printer is pre-installed, and the assembly requires only 3 steps. Friendly enough to...

- 2.CR Touch Auto Bed Leveling: Upgraded CR Touch 16-point automatic bed leveling technology saves you in the trouble of manual leveling. Easy to use,...

- 3.Brand New 4.3 Inch UI User Interface: The upgraded UI adds a model preview function, making it easier to observe the printing shape and progress for...

Mass is critical for NASA’s future deep space missions. Projects like this mature additive manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA’s ambitious missions to the Moon, Mars, and beyond,” said John Vickers, principal technologist for STMD advanced manufacturing.