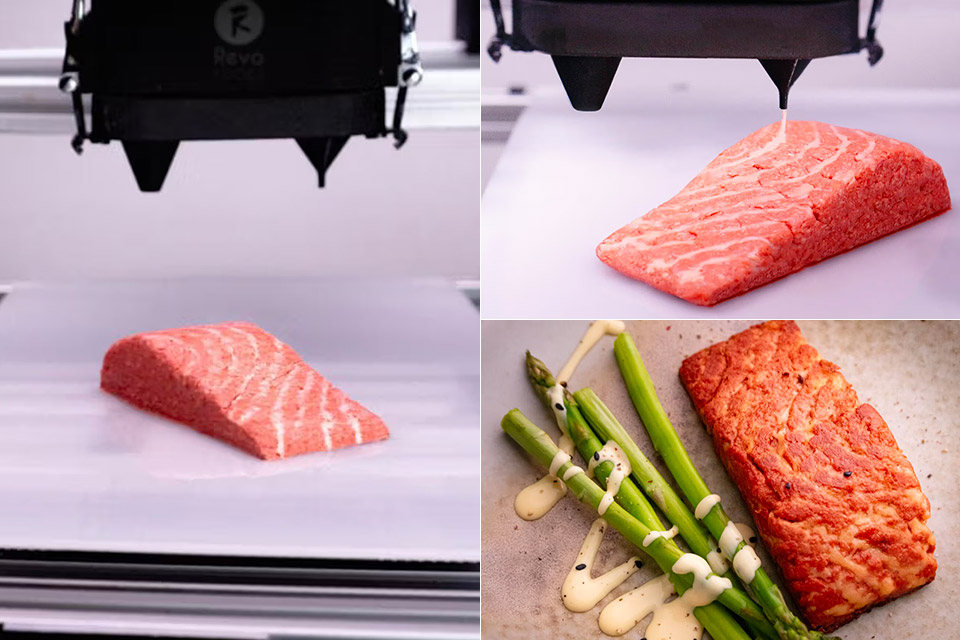

Ausria-based Revo Foods has launched their 3D-printed vegan salmon filet made with mycoprotein at REWE supermarket. This also marks the first time that a 3D printed food is available in supermarkets, which means the technology is now ready to finally scale to industrial volumes.

The company developed a new extrusion technology that allowed them to seamlessly integrated fats into a fibrous protein matrix, leading to more authentic seafood alternatives with the familiar flakiness as well as juicy taste of fish filets. When combined with Revo Foods’ 3D-MassFormer, the system becomes the first ever continuous production process capable of mass-producing 3D printed food. Mycoprotein requires only minimal processing and fewer resources, like water, in its production compared to traditional fish production.

- OVERVIEW OF NEPTUNE 3 PRO: 225x225x280mm/8.85x8.85x11 inch printing size can meet the needs of most users. With an STM32 motherboard, all axes of...

- DUAL-GEAR DIRECT EXTRUDER: The new direct drive extruder is made of SUS303 high-quality stainless steel with a 3:1 reduction ratio and stronger...

- NOZZLE KIT FOR BETTER PRINTING: The nozzle kit contains a TC4 titanium alloy throat pipe, an aluminum alloy flat heat sink structure, and a brass...

With the milestone of industrial-scale 3D food printing, we are entering a creative food revolution, an era where food is being crafted exactly according to the customer needs. We are not just creating a vegan alternative; we are shaping the future of food itself,” said Robin Simsa, CEO of Revo Foods.