Photo credit: Max Planck Society | Fast Company

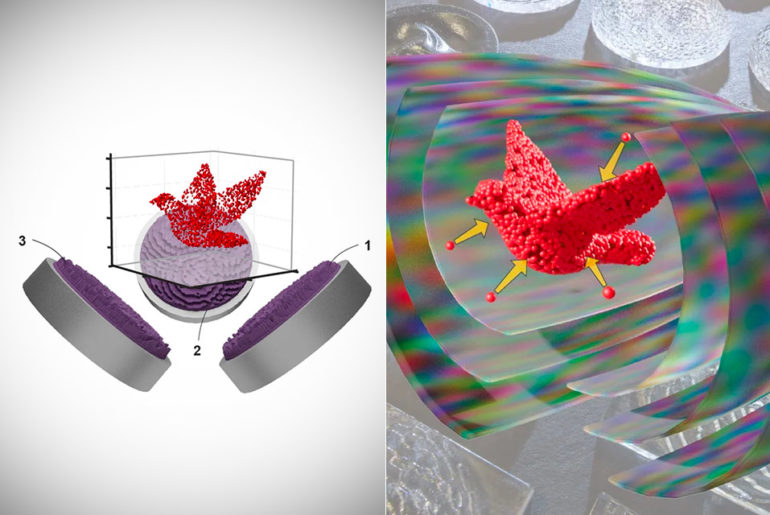

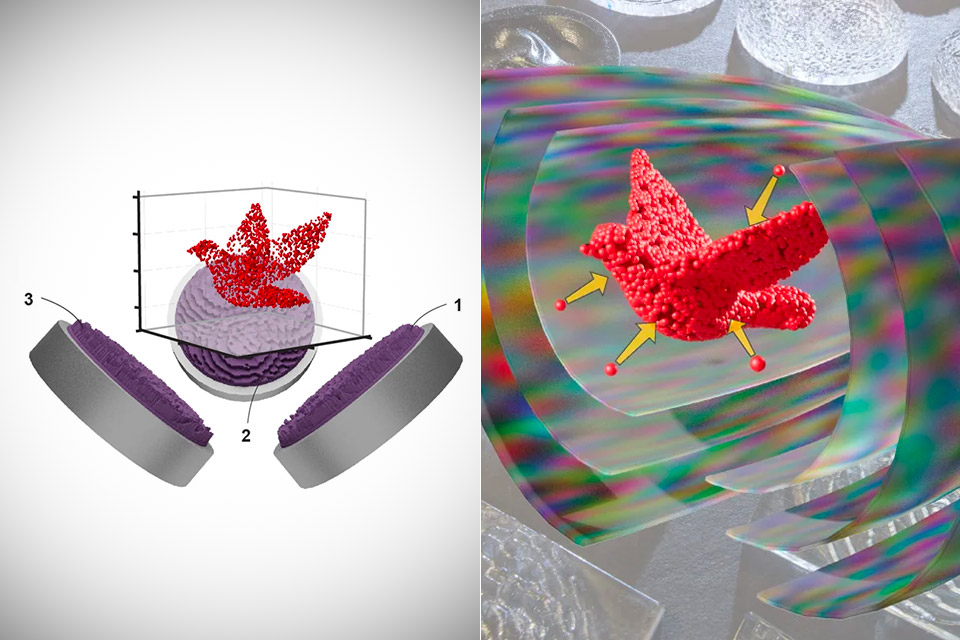

You won’t be able to recreate Google’s Project Starline, but researchers from the Max Planck Institute for Medical Research and Heidelberg University have developed a machine that can 3D print with ultrasonic holograms, or sound waves. This touchless 3D printing method can be used to form any shape desired using those sound waves.

Since ultrasound is gentle and non-toxic to cells, it can be used for remote assembly without contact for living tissue in the future. Put simply, the researchers combined multiple holographic fields that drive the contactless assembly of solid microparticles, hydrogel beads, as well as biological cells inside standard lab equipment. These structures can then be fixed via solidification of the surrounding medium.

- Resume Printing Function: no worry to the immediate power outage or electric circuit error, Ender 3 has the ability to resume printing even after a...

- Creality Ender 3 3d printer, it is the most basic 3d printer model, more students and beginners can learn the 3d printer by this model, it can help to...

- Advanced Extruder Technology: Ender 3 upgraded extruder greatly reduces plugging risk and bad extrustion; V-shape with POM wheels make it move...

In contrast to previous work, this approach handles matter with positive acoustic contrast and does not require opposing waves, supporting surfaces or scaffolds. We envision promising applications of 3D holographic ultrasound fields in tissue engineering and additive manufacturing,” said the researchers.