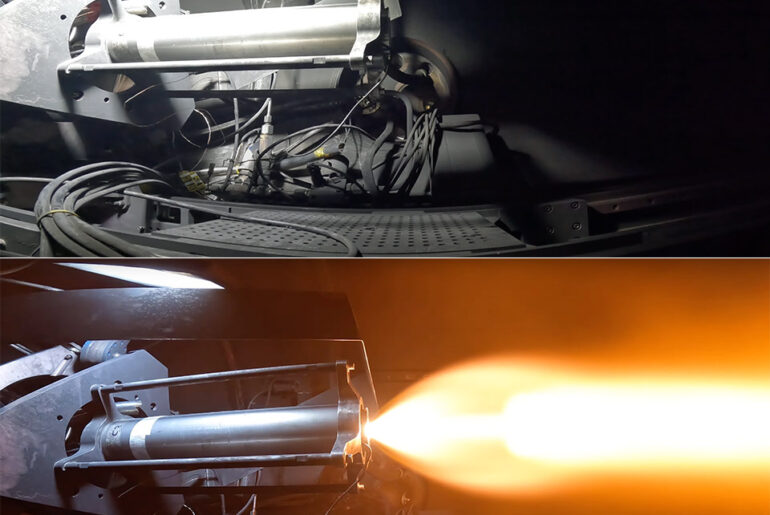

Engineers at NASA’s Marshall Space Flight Center in Huntsville, Alabama, successfully tested a 14-inch hybrid rocket motor this week, a big step toward safer and better lunar landings. Why hybrid? These motors mix solid and liquid fuels, giving a special combo of safety, control, and power.

The motor was made through NASA’s Space Technology Mission Directorate’s Game Changing Development Program, with help from Marshall’s Propulsion Department and partners like Gloyer-Taylor Laboratories. This 14-inch motor is a smaller test version, but it’s a key proof that bigger versions could power human landing systems from companies like SpaceX and Blue Origin. These systems are super important for safely getting astronauts to and from the Moon’s surface, especially for Artemis III (planned for mid-2027) and future missions.

- NASA rocket model kit – Launch into a creative project with the LEGO Icons NASA Artemis Space Launch System model building project for adult space...

- What’s in the box? – This creative building set includes everything you need to craft a multistage rocket with 2 solid-fuel boosters, an Orion...

- Features and Functions – This NASA-themed rocket model features retractable launch tower umbilicals, rocket support and crew bridge, detachable...

Unlike regular solid rocket motors, which burn nonstop and can’t be adjusted, hybrid motors (using solid fuel and liquid oxidizer) can be throttled—you can turn their power up or down. If a landing has to be paused or tweaked, the motor can turn off and fire up again. This adaptability is really important for astronaut safety and mission success.

Hybrid motors are safer than typical liquid or solid rockets. They’re less likely to have major explosions since the solid fuel and liquid oxidizer stay separate and only combine during burning. For Artemis missions carrying astronauts, this cuts down risks during launch, travel, and landing. The motor’s design also simplifies handling and storage, which is awesome for lunar landers that may need to operate alone or sit on the Moon for extended periods.

We’re bringing back the capability to characterize the effects of rocket engines interacting with the lunar surface through ground testing in a large vacuum chamber — last done in this facility for the Apollo and Viking programs. The landers going to the Moon through Artemis are much larger and more powerful, so we need new data to understand the complex physics of landing and ascent. We’ll use the hybrid motor in the second phase of testing to capture data with conditions closely simulating those from a real rocket engine. Our research will reduce risk to the crew, lander, payloads, and surface assets,” said Ashley Korzun, principal investigator for the plume-surface interaction tests at NASA Langley.