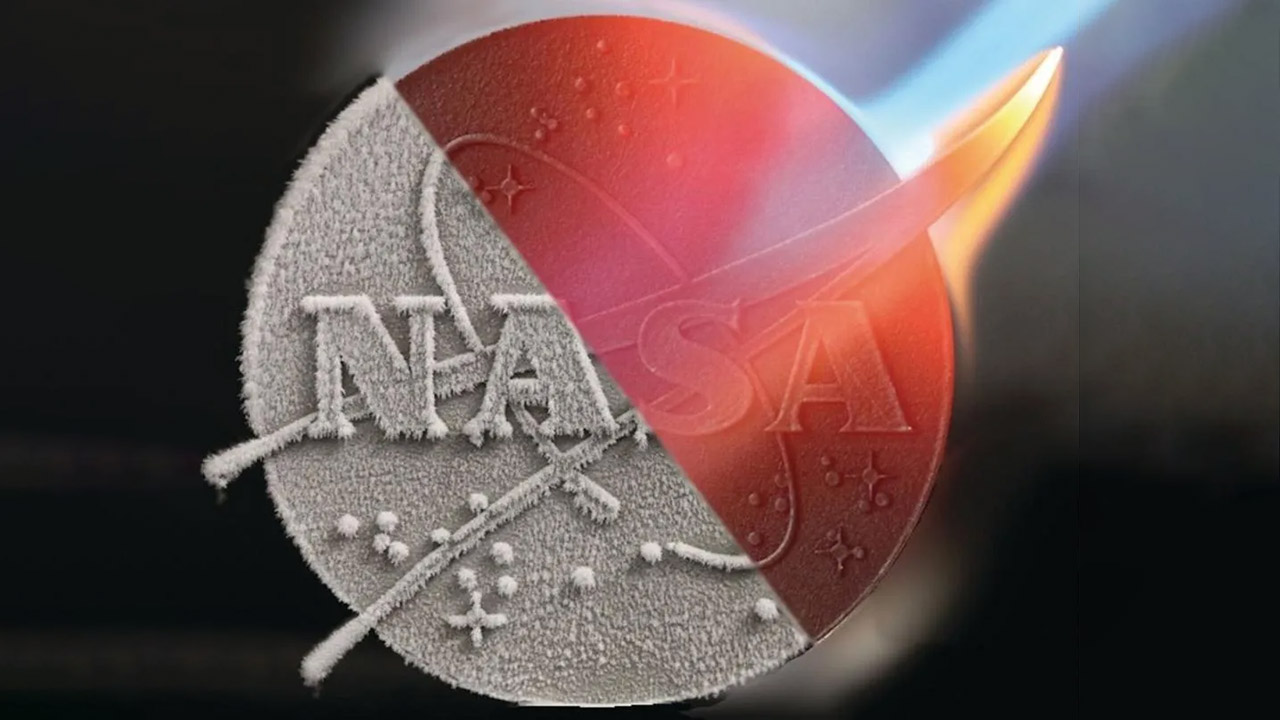

NASA’s Glenn Research Center in Cleveland, Ohio has created a metal alloy that can withstand what others can’t. Meet GRX-810, a material that can handle the heat of rocket engines and jet turbines, signaling a gigantic leap forward for 3D printing in aerospace.

GRX-810 is an oxide dispersion strengthened (ODS) alloy, a blend of nickel, cobalt and chromium with a ceramic oxide coating. The coating is the secret to its heat resistance. It’s applied to tiny metal particles through a process called resonant acoustic mixing. Imagine a container vibrating rapidly, tossing metal powder and nano-oxide particles together until each grain is coated. This creates a bond so tight that even if the alloy is ground back into powder, the oxide stays put, so every new part has the same durability. Unlike other alloys which might crack or deform under heat and stress, GRX-810 holds strong, up to a year at 2,000°F compared to hours for other affordable metals.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000...

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make...

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,...

Creating ODS alloys used to be a costly and time consuming process. NASA’s breakthrough came from combining computational modeling with 3D printing. Researchers used thermodynamic simulations to dial in the alloy’s composition in 30 tries – a process that used to take years of trial and error. This modeling didn’t just pick the metals, it calculated the exact amounts needed for optimal performance, cutting costs and dead ends. The 3D printing process then disperses the oxide particles uniformly, boosting the alloy’s high temperature strength and making production cleaner and more efficient than traditional methods.

The alloy’s performance is amazing, since at 2,000°F, GRX-810 has twice the strength to resist fracture, three and a half times the flexibility to bend without breaking, as well as over 1,000 times the durability under stress than other alloys. This means parts made from GRX-810 can last longer inside rocket engines or aircraft turbines, reducing the need for frequent replacements. It also allows for more complex designs, as 3D printing frees engineers from the constraints of traditional manufacturing, enabling shapes that were once impossible to produce.

Beyond NASA’s own uses, GRX-810 is making waves in the commercial world. Elementum 3D, a Colorado based company, has a co-exclusive license to produce the alloy in quantities from small batches to over a ton. Their large scale production has already doubled the life of parts compared to initial testing which was impressive to begin with. One customer, Vectoflow, is testing GRX-810 for flow sensors that monitor gas speed in turbines. These sensors often burn out quickly in extreme heat, but GRX-810 versions could last longer, improving fuel efficiency and reducing emissions in airplanes. The alloy’s versatility suggests it could be used in other high heat industries, from power generation to advanced manufacturing.