Sharon Aluma stands in the center of what appears to be a typical loading dock in America, but there are no forklifts in sight. As the product manager for Stretch at Boston Dynamics, she understands that this is not for show. It’s a complete warehouse squeezed inside a test facility, with banging metal doors and the faint odor of cardboard dust. The engineers here spend their days watching Stretch, the company’s box-hauling robot, grapple with the same freight that powers e-commerce titans.

Walk past the main unloading bays, and the space expands to demonstrate how far Boston Dynamics goes to make this feel real. Trailers line up against a row of massive doors, their innards crammed with the kinds of shipments that arrive daily at distribution centers: towering pallets of shrink-wrapped items, loose boxes of consumer electronics, and endless piles of various box sizes. They do not cut corners. They match customer drawings down to the bolt, the conveyor belts that snake across the floor, and even the modest inclination of the ramps where vehicles return.

- LEGO SET FOR ADULTS – The WALL-E and EVE (43279) building set offers adults 18 years old and up an immersive construction challenge featuring...

- 4 DISNEY PIXAR CHARACTERS – Builders can create iconic robots WALL-E, EVE, M-O and Hal from the hit movie—each with authentic functionality like...

- MINDFUL BUILDING EXPERIENCE – This detailed construction set lets builders practice advanced construction techniques for an immersive and relaxing...

Boxes tell their own story in this lab, a procession of shapes and surprises that Stretch learns to handle without batting an eye. Engineers load up trailers with everything from featherlight packages no bigger than a shoebox to 50-pound behemoths, their surfaces covered in glossy labels or faded shipping tape. Not all freight is well-behaved; some cases have irregular edges or slick finishes that make it hard to get a grip. To keep things real, the team rebuilds mockups to match exact customer loads—down to the weight distribution inside—or goes straight to the source, accepting shipments of actual products from partners who don’t want surprises on their floors.

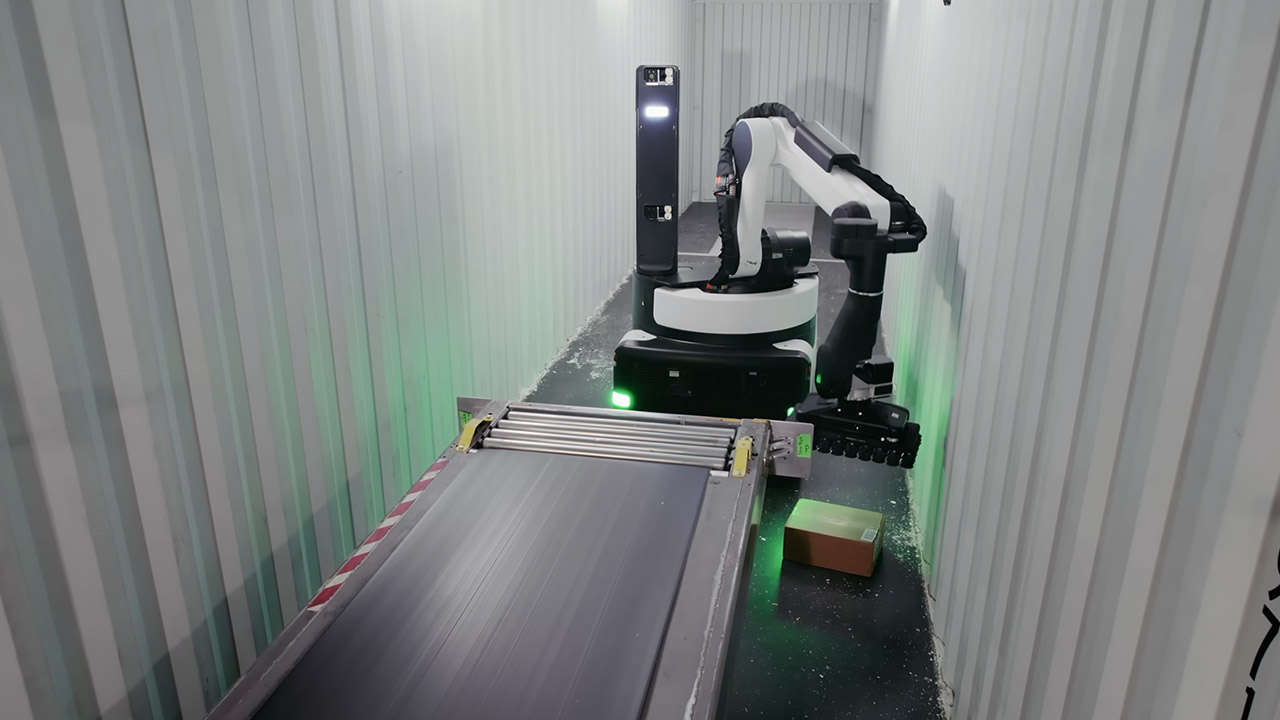

Switching from one trailer to the next is smoother than you’d expect thanks to the quiet intelligence built into Stretch. Finish unloading a load and the robot doesn’t wait for a human to nudge it. It backs up on its own, the conveyor retracts like an accordion as it pulls out of the trailer. Any boxes left behind get scooped up along the way, no second trip required. At the door a single operator steps in to steer to the next bay, flip a switch and the cycle starts again.

Endurance is at the far end of the lab, where rows of devoted cells transform Stretch into a workhorse under fire. Robots do the same motion—grasp, lift, place, and repeat—for hours on end, straining joints and circuits to their limits. Engineers monitor the screen readouts for slight wear, such as a heated motor or a sensor fogging from frequent dust exposure. Failures occur here, not at a distant warehouse at 3 a.m.