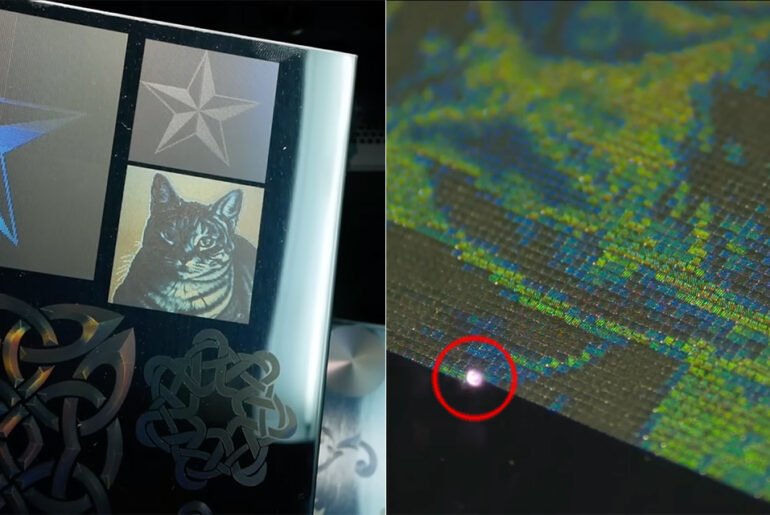

Ben Krasnow took a MOPA fiber laser and turned it into a canvas for something amazing. His latest project shows what this high precision laser can do to stainless steel to create shimmering diffraction gratings that look like holograms.

Stainless steel, industrial and unassuming, is the star of the show. When heated it forms a thin oxide layer on the surface, the thickness of which varies with temperature. This oxide acts as a prism, splitting light by thin film interference to produce yellows, magentas, blues and greens that change with angle of view. Krasnow’s MOPA laser, a Cloudray GM-100 NEO, can deliver precise bursts of radiation so he can control the heat with surgical precision. He can vary the pulse length and repetition rate to achieve specific oxide thicknesses and paint steel in different colors. This is the core of his art but the real magic happens when he takes it a step further and carves patterns that make light ripple and bend.

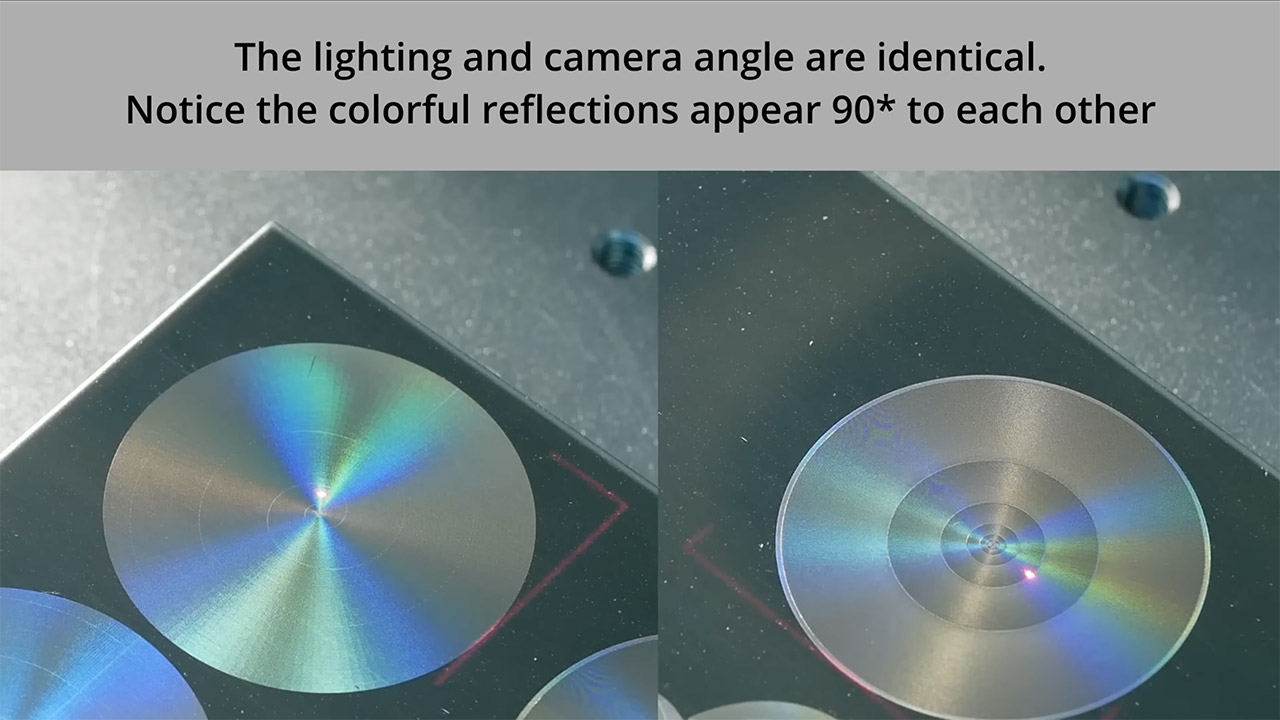

- 【Ready to Use, Craft Easier】Ready to use straight out of the box. Falcon A1 10w laser engraver has pre-set different optimal parameter settings...

- 【Smart Camera】The laser engraver machine, equipped with a pre-calibrated HD camera, offers you a full-frame view of the engraving area, allowing...

- 【3 Times Faster】Falcon A1 adopts the latest CoreXY Motion System Technology and Dual Motor Power System, which enables the machine's engraving and...

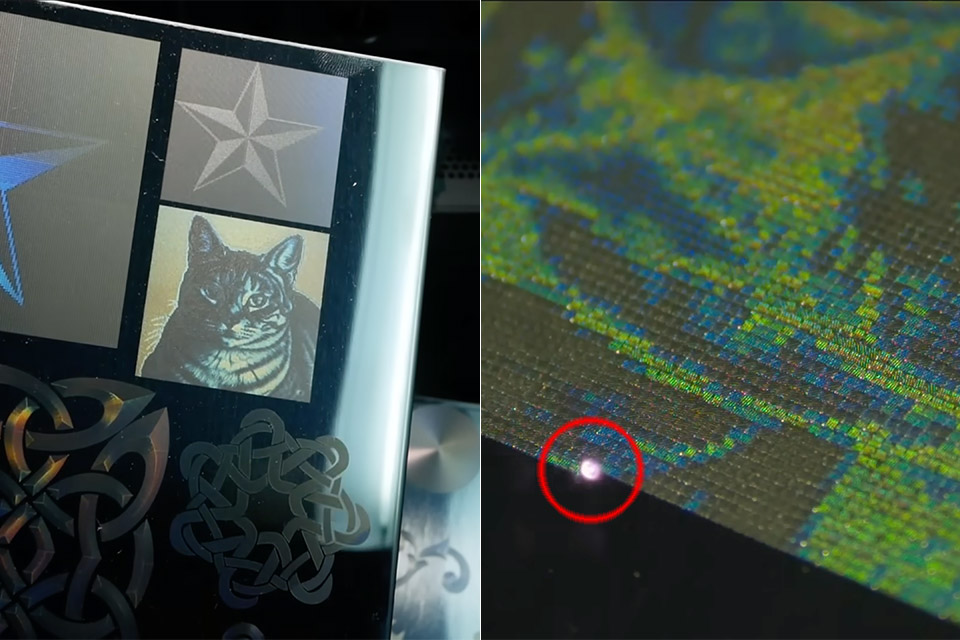

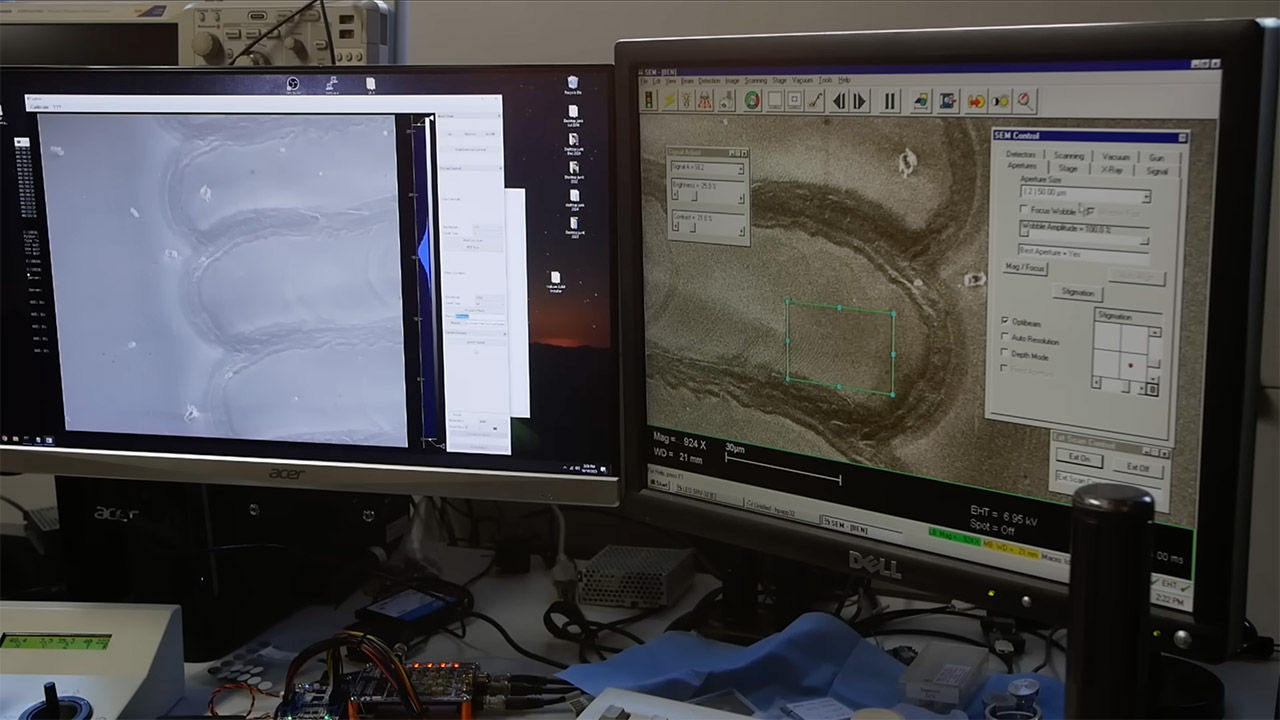

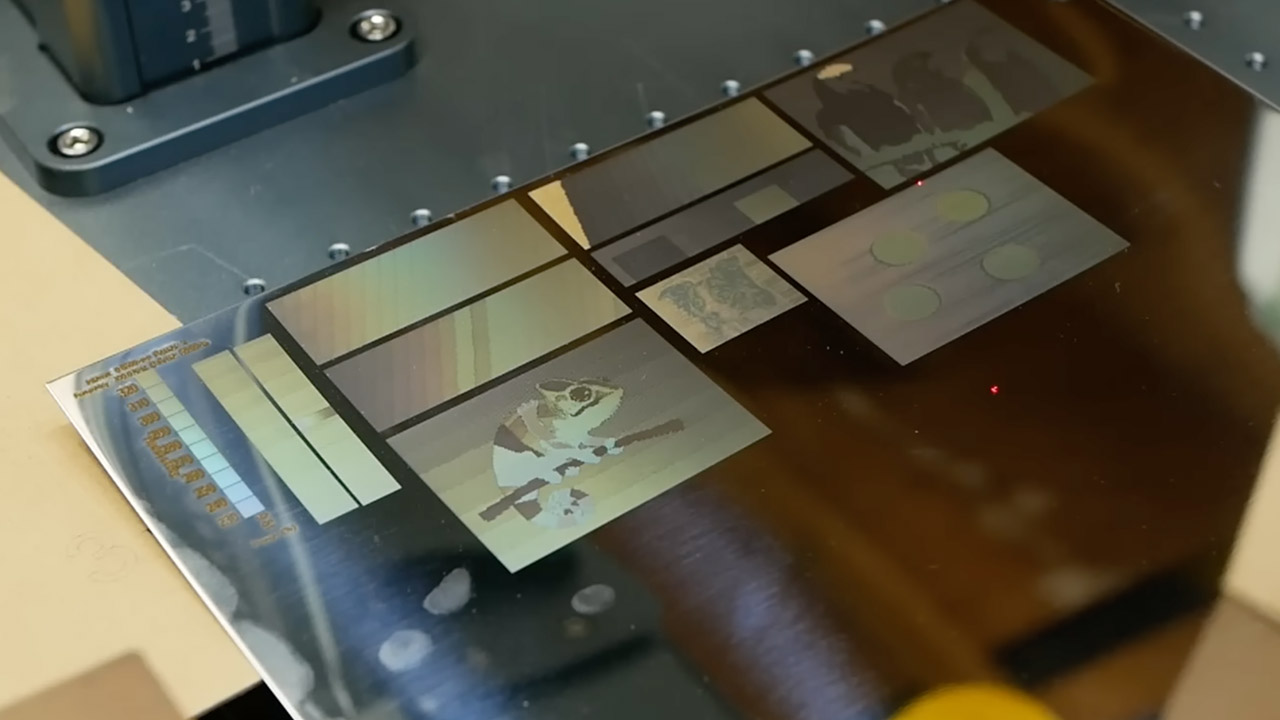

Krasnow’s almost-holograms are built on diffraction gratings, tiny periodic structures that split light into its component wavelengths. With the MOPA laser he etches parallel lines of oxide onto the steel, each spaced to the micron. These lines act as a grating, diffracting light, producing iridescent effects like the surface of a CD. Unlike laser engraving, which removes material, this procedure is far more sensitive. The oxide layer penetrates the metal, and the surface is practically flat. Krasnow discovered this by electron microscope imaging, which revealed that diffraction is generated by changes in oxide thickness, not physical ridges. This was a huge surprise because he had intended to use the etched steel as a mold for diffraction-patterned chocolate, but it turned out to be something far cooler.

His experiments really take off when he starts playing with the pitch and direction of the gratings. This allows him to change the angle of the diffraction by adjusting the spacing between the lines, resulting in all sorts of visual effects. He wrote Python scripts to convert black and white images into diffraction grating arrays and put them on his GitHub. Each pixel in these images becomes a small grating, with the orientation determined by the pixel’s brightness. The end result is a glittering, dynamic image that changes as you tilt it, like the parallax of a real hologram.

Experimenting with true color diffraction will enable him to take it even further. A grating with uniform spacing gives a rainbow effect when the viewing angle changes, but by incrementally changing the pitch across the grating, he can have a single color dominate at a given angle. He can etch images – a bright bird or a gecko – where blues are blue and reds are red at least from one angle. Is there a catch? The viewing angle is tricky, it’s more like a proof of concept art piece rather than a functional display. However, the precision required to do this is mind boggling and Krasnow’s scripts, made with the help of AI tools like Gemini, can be used by anyone with a MOPA laser and some coding skills.

The setup is noteworthy because Krasnow employs a vacuum chuck to maintain the steel flat, preventing the warping that thin sheets are prone to. This chuck, a lucky eBay find, also serves as a heat sink, preventing the laser’s intensity from bending the metal. The Cloudray GM-100 NEO, a 100w monster, only uses roughly 20% of its power for these little engravings, implying that even lower-wattage versions may work. LightBurn software drives the process, and it includes a material test capability that allows Krasnow to change parameters over dozens of repetitions.

[Source]