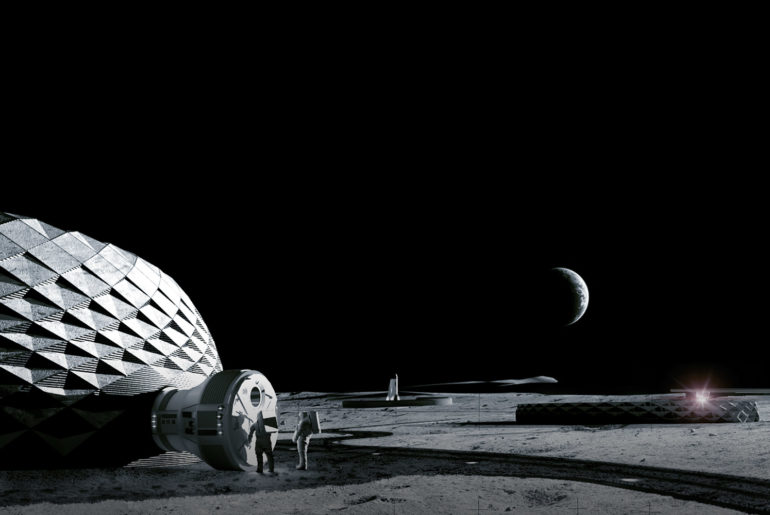

Photo credit: BIG-Bjarke Ingels Group

BIG-Bjarke Ingels Group partnered with construction technology company ICON, SEArch+ (Space Exploration Architecture) and NASA to develop “Project Olympus,” a space-based construction system that could support future exploration of the Moon. The main goal is to ensure the safety of astronauts and to do so, the team believes that 3D printing with indigenous materials is the best way to go. This will not only offer a practical solution, but also prove to be critically vital to human survival both Earth and in space.

One challenge in the 3D-printing process is going to be the task of obtaining regolith, which is basically a fine gray powder that consists of useful minerals (basalt, feldspar, etc.) to be used as a printing medium through melting or sintering. This molten material will then be fed into the machine to create vaulted structures made from a waffle-like network of rigid exterior ribs and then filled with regolith, which doubles as a solar radiation absorber.

- Feed a passion for science and technology – Kids can learn more about the challenges of space exploration with this LEGO Technic NASA Mars Rover...

- Conduct a test flight – This advanced building kit for kids ages 10 and up includes a buildable toy version of NASA’s Ingenuity helicopter, which...

- AR brings the mission to life – The accompanying augmented reality app experience lets kids dive into the details of the rover and its mission

Building on our experience with BIG’s Mars Science City, we are working to develop the first permanent structure on the Moon resilient to the hostile lunar environment where the cost of payload transportation requires rigorous efficiency. We have explored various building forms ideal for containing atmospheric pressure and optimized for protection from cosmic and solar radiation. The habitat will be designed with the inherent redundancy required for extraterrestrial buildings, while also using groundbreaking robotic construction that uses only in-situ resources with zero-waste left behind, said Martin Voelkle, Partner, BIG.