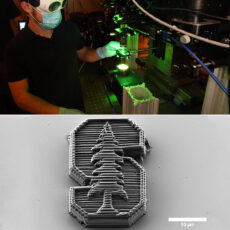

MIT researchers have developed a new 3D printing method that uses liquid metal to produce large-scale parts like table legs and chair frames in mere minutes. Called liquid metal printing (LMP), the technique involves depositing molten aluminum along a predefined path into a bed of tiny glass beads.

The aluminum then quickly hardens into a 3D structure and at speeds of at least 10 times faster than a comparable metal additive manufacturing process. Even more impressive is that the procedure to heat and melt the metal is more efficient than some other methods. One caveat: the method is not capable of achieving high resolutions, thus making it perfect for some architecture as well as construction applications.

- Resume Printing Function: no worry to the immediate power outage or electric circuit error, Ender 3 has the ability to resume printing even after a...

- Creality Ender 3 3d printer, it is the most basic 3d printer model, more students and beginners can learn the 3d printer by this model, it can help to...

- Advanced Extruder Technology: Ender 3 upgraded extruder greatly reduces plugging risk and bad extrustion; V-shape with POM wheels make it move...

This is a completely different direction in how we think about metal manufacturing that has some huge advantages. It has downsides, too. But most of our built world — the things around us like tables, chairs, and buildings — doesn’t need extremely high resolution. Speed and scale, and also repeatability and energy consumption, are all important metrics,” said Skylar Tibbits, associate professor in the Department of Architecture and co-director of the Self-Assembly Lab.

[Source]