Photo credit: Dan DeLong for Microsoft

Cooling computer chips is a quiet war in the tech world; as AI pushes silicon to the limit, they are hotter than ever and traditional cooling is failing to keep up. Microsoft’s new discovery, microfluidics, can change the game by cooling from within.

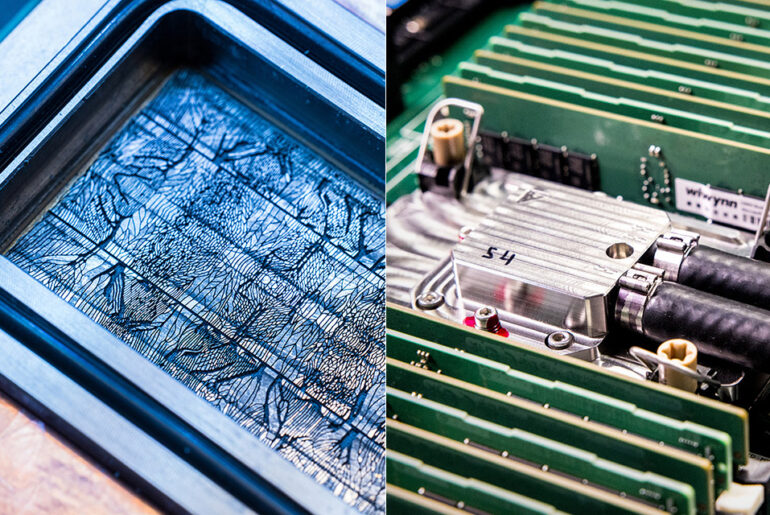

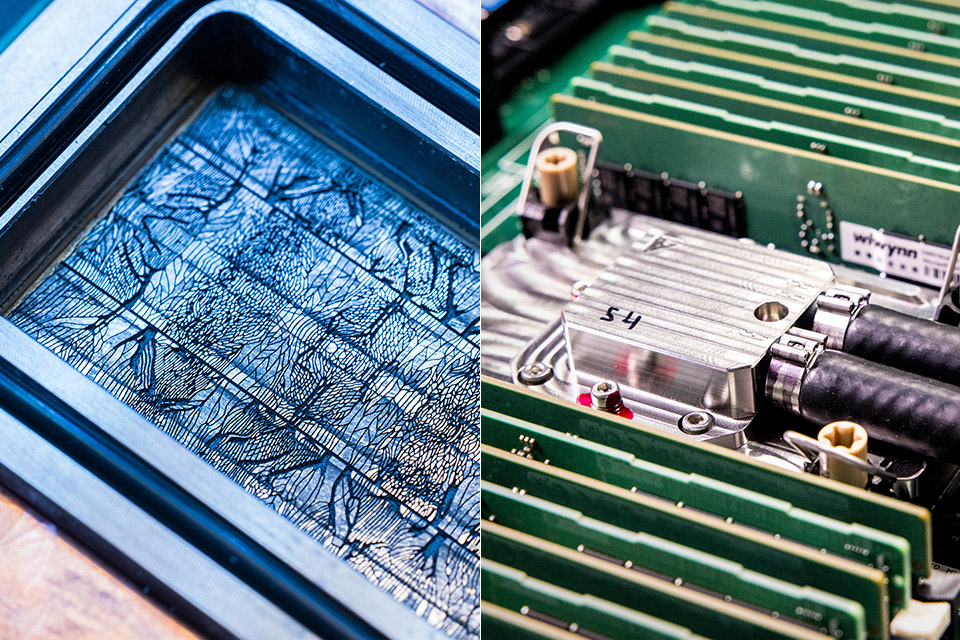

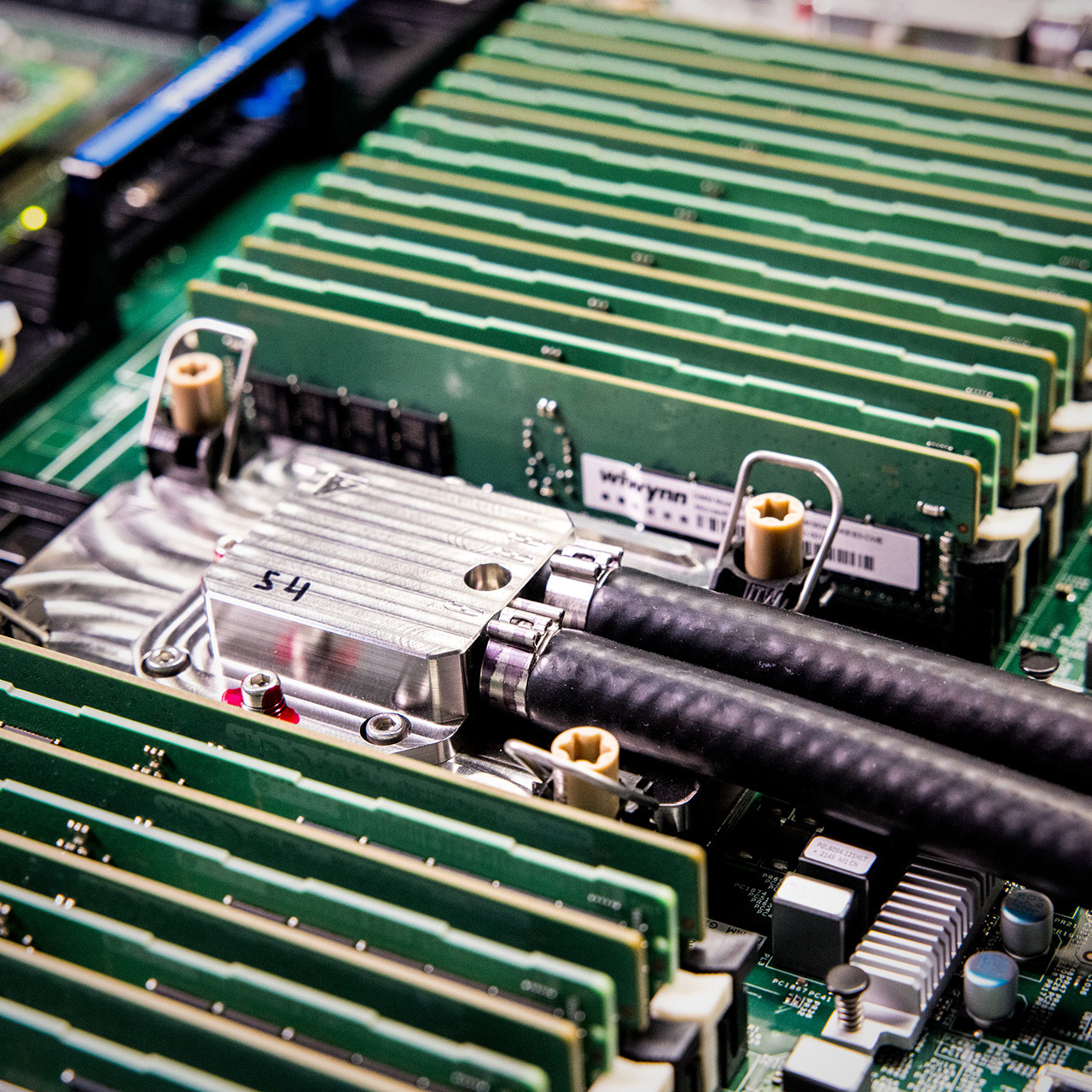

Microfluidics works by carving microscopic grooves into the back of a silicon chip, so liquid cooling can flow directly where the heat is generated. These grooves, about the diameter of a human hair, are little rivers that remove heat faster than the copper plates used in many data centers today. Microsoft’s testing showed this can remove heat up to three times better than those plates, reducing the maximum temperature rise in a chip by 65%. This cooling solution kept a server running a simulated Microsoft Teams meeting stable.

- Purposeful Design: Travel with ease and look great doing it with the Aspire's 3 thin, light design.

- Ready-to-Go Performance: The Aspire 3 is ready-to-go with the latest AMD Ryzen 3 7320U Processor with Radeon Graphics—ideal for the entire family,...

- Visibly Stunning: Experience sharp details and crisp colors on the 15.6" Full HD IPS display with 16:9 aspect ratio and narrow bezels.

Designing these grooves is not an easy task as they need to be deep enough to transfer enough liquid but not so deep the chip becomes unstable. Microsoft worked with a Swiss company, Corintis, to refine the design, borrowing from nature. The grooves mirror the branching patterns of veins in a leaf, directing coolant to the hottest parts of the chip. AI also played a role, monitoring heat patterns to see where the liquid flows. It’s a delicate balance of engineering and art that keeps the chip stable while the coolant does its job.

This is important because current chips, especially those used in AI, generate a lot of heat as they process huge amounts of data. Traditional cooling methods, like fans blowing air or copper plates with liquid flowing across them, can’t keep up. These technologies use layers of material between the chip and the coolant that act as blankets, trapping some heat. Microfluidics removes those layers, so the coolant can touch the silicon directly. That means the liquid doesn’t need to be as cold to work, saving the energy that would otherwise go to chilling it.

Data centers, the backbone of services like cloud computing and video calls, will benefit big time. Take a Microsoft Teams call for example. Hundreds of services work together to connect people, host chats, blend audio and transcribe speech. These tasks spike at predictable times like the start of a meeting and servers get maxed out. To handle these spikes, companies either add more servers which are usually idle or overclock current ones. Overclocking generates more heat which can damage the chip. Microfluidics could let servers run faster without overheating, reduce costs and increase reliability.

In the future, this technology could completely change semiconductor architecture. Stacking chips in 3D could make them faster by reducing the distance data travels, but heat has been the barrier. Microfluidics could fix this by routing coolant through tiny pillars between stacked chips, like pipes in a skyscraper. This could lead to smaller, more powerful data centers and push the limits of computing.