A University of Edinburgh crew just nailed a Blade Runner-worthy feat, 3D-printing soft robots that crawl right off the printer, no assembly needed, ready to scuttle around. These palm-sized, four-legged bots, driven by air pressure, are a big step for robotics, with potential to tackle everything from disaster zones to medical breakthroughs. Led by PhD student Maks Gepner, the project flips traditional robot manufacturing on its head with a clever, low-cost printing system that’s as accessible as it is groundbreaking.

Soft robots aren’t entirely new—researchers have been tinkering with flexible, squishy machines for years. Unlike their rigid, metal-clad cousins, these pliable creations can squeeze into tight spaces, absorb impacts, and interact safely with humans. But making them has always been a hassle, often requiring complex assembly or pricey equipment. Gepner’s team at Edinburgh’s School of Engineering sidesteps those hurdles with a novel 3D printing method that builds robots in one go. “We’ve developed a system where the robot is printed upside-down, fully formed, and walks off the printer as soon as it’s done,” Gepner explains. The result? A robot that’s ready to scuttle away the moment its umbilical air tube is detached.

- Speedy with CoreXY and Easy to Start: K1 SE inherits the lightweight and agile CoreXY system of the K series. It offers a thrilling max printing speed...

- Auto Leveling and Z-offset: Creality K1 SE 3d printer, its auto-calibration gets everything ready, with one tap. Bid farewell to the frustrating...

- Flagship Extrusion Kit and 60 Watt Hotend: K1 SE uses the same extruder as K1C, it feeds the filament precisely without any slacking. The extruder,...

The Flex Printer is basically a desktop setup costing under £400, cobbled together from off-the-shelf parts. “Building and operating the Flex Printer requires little prior knowledge,” says Jonah Mack, a fellow PhD student on the project. “First-time users can start making robots in just a few days.” The team’s open-source approach amplifies its reach, with designs freely available to spark collaboration and innovation.

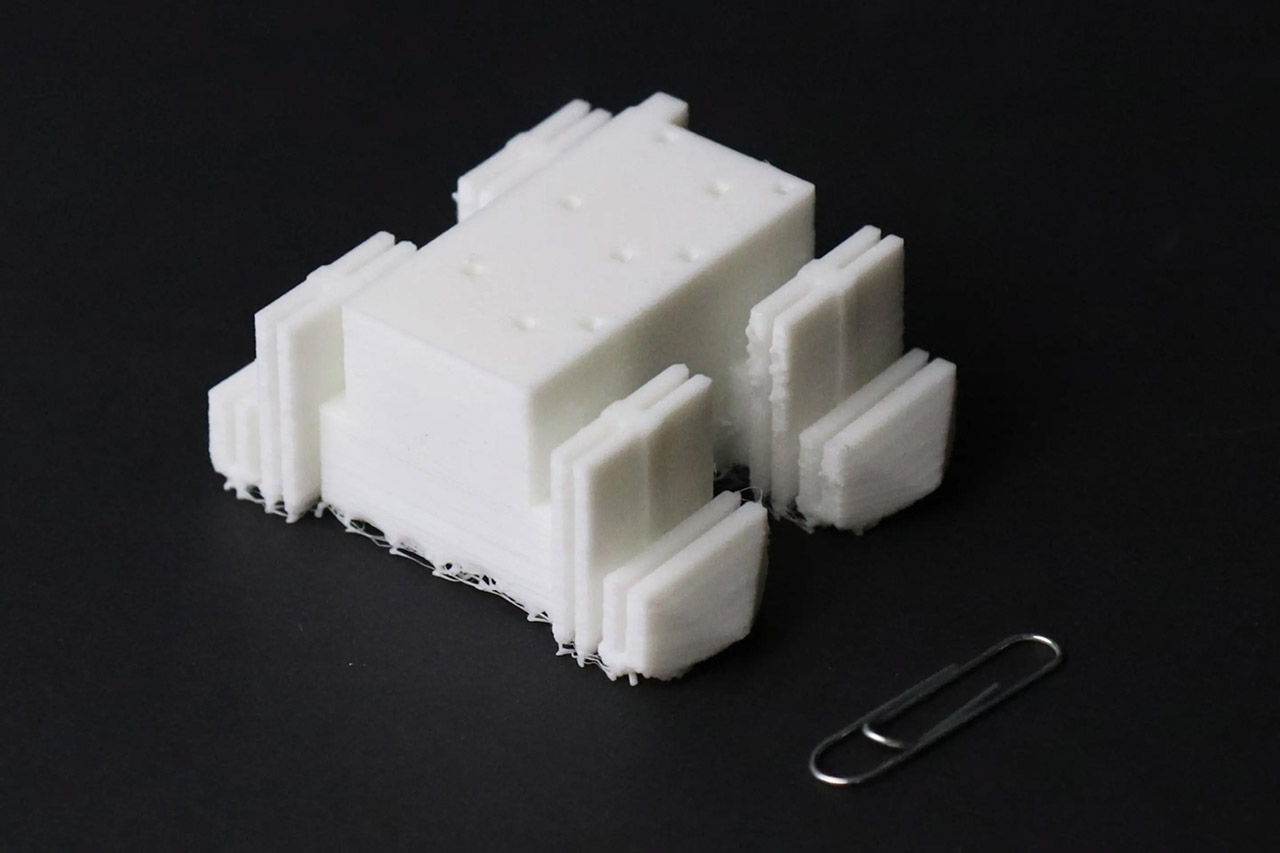

The robots themselves are made from soft plastics, their movements driven by internal fluidics—think air-filled channels that flex and contract to mimic muscle motion. These “strategically geometric designs,” as the team calls them, are embedded during printing, allowing the robots to walk in pre-programmed patterns. Picture a tiny, squidgy quadruped, not unlike a baby Wall-E, toddling off the print bed. “The ability to integrate fluidic systems directly into the printing process is a game-changer,” says Professor Adam A. Stokes, head of Edinburgh’s Institute for Bioengineering and the project’s lead academic. “It eliminates the need for post-print assembly or electronic components.” This simplicity slashes costs and time, making scalable production a real possibility.

Their flexibility makes them ideal for navigating tricky environments, whether it be nuclear decommissioning, where they could slip through radioactive rubble, or biomedicine, where they might deliver drugs inside the body. Space exploration is another frontier; their durability and light weight suit them for extraterrestrial terrain. “Soft robots are versatile, durable, and generally beneficial across industries,” Gepner notes, highlighting their potential to transform fields from healthcare to disaster response. The fact that they’re made from cheap, pliable materials only sweetens the deal.

Edinburgh’s method, built on the open-source Flex platform, keeps costs as low as $500 for the entire system. This thriftiness doesn’t sacrifice function, either. The robots are robust, able to handle rough handling and tight spaces that would trip up rigid machines. “Our version is the most cost-effective to date,” Gepner asserts, a claim backed by the team’s focus on accessible, scalable tech.

[Source]