![]()

In Austin, Texas, a city dealing with increasing housing costs, a quiet revolution is taking place on the outskirts of the Mueller neighborhood. ICON, a local construction company that pushes the boundaries, is employing 3D printing technology to build 12 homes. Three of these homes, each a 651-square-foot bungalow, are available to low-income buyers under the Mueller Affordable Homes Program.

These homes are in Mueller, a 700-acre redeveloped former airport, now a mix of single-family homes, apartments, shops and parks. The neighborhood, just 3 miles from downtown, has urban energy and green spaces – 144 acres of parks and trails run through it. ICON’s project, with Michael Hsu Office of Architecture and developer Catellus, adds to Mueller’s story. The homes, one to three bedrooms, are along the Southwest Greenway with views of a golf course and hiking trails. It’s a great spot, walkable to restaurants, an H-E-B grocery store and cultural hubs like The Thinkery children’s museum.

- 【12X Speedy with CoreXY】K1 SE 3D Printer inherits the lightweight and agile CoreXY system of the K1 series. Max 600mm/s speed and 20000mm/s²...

- 【Flagship Reliable Extruder】Crealitry k1 se uses the same extruder as k1c. The extruder equipped with a newly added side spring & ball plunger,...

- 【Durable Tri-metal Nozzle & 60W Hotend】Easy to maintain & quick to swap. The durable steel-tipped copper nozzle is integrated with a titanium...

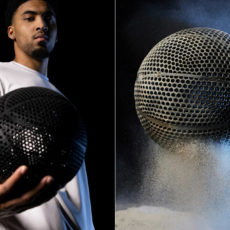

Construction here is unlike anything you’d see on a typical job site. ICON’s Vulcan printers, giant robotic arms powered by a 60 kVa generator, hum as they extrude a proprietary cement-like material called CarbonX. Layer by layer, they form the lower floor’s walls, creating a shell with a ribbed texture. It’s fast – walls go up in 2-4 weeks vs months for traditional methods. Human builders then take over, adding timber-framed upper levels, standing seam metal roofs, windows and doors. The result is a hybrid: cutting edge tech for the base, familiar craftsmanship for the rest.

Each contains a living room, dining area, and kitchen on the first floor, making the 651 square feet feel open rather than cramped. A single bedroom and bathroom are located upstairs, offering a private retreat. The walls, built of low-carbon concrete, provide insulation, keeping homes cool in Austin’s hot summers and comfortable in its mild winters.

The neighborhood’s Affordable Homes Program, run by the Mueller Foundation, ensures 25% of its housing – over 1,725 units when complete – will be for households earning up to 80% of the area’s median income, about $58,525 in Travis County. For context, Austin’s median household income is $97,543. The program targets seniors and families, a lifeline in a city where costs are pushing many out. ICON’s three bungalows are a small but important part of this, with nearly a dozen more two and three bedroom homes in the works, priced from $350,000 to $1.3 million.

Vulcan printers need only one operator and a small crew, cutting labor and time. The company claims it uses 30% less material than traditional construction. This doesn’t sacrifice quality—Michael Hsu’s designs bring clean lines and natural materials like wood and stone to the homes.

The $195,000 price tag for the bungalows raises an eyebrow. In Austin, where a basic home can easily top $400,000, it’s a steal, but not cheap. At $300 per square foot, it’s more than Texas’s average build cost of $180 to $280 per square foot (though that includes land in a hot neighborhood). Mueller’s market-rate 3D printed homes start at $350,000 and go up to $1.3 million for the larger models. The cost reflects the premium location and the tech, but it’s still a stretch for some. Monthly mortgage payments of $1,000 to $1,500 are in line with a one-bedroom apartment in Austin, so it’s possible for working-class buyers to own.

[Source]