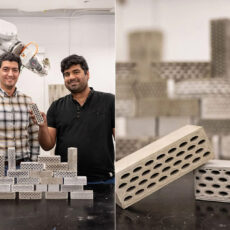

Photo credit: OSU

In the Oregon State University lab, a group of researchers have found a solution to one of the construction industry’s longest-running problems. For years, Devin Roach and his team have been fine-tuning a pretty basic combination of dirt to come up with a material that can be printed into walls right on the spot and stand up on its own without any waiting around. The result is a mix of soil, hemp fibers, sand, and biochar that comes out of a 3D printer’s nozzle and sets almost as fast as the layer touches the air.

Clay is the base material here, straight from the ground and mixed in with some hemp strands to give it a bit of flexibility and then sand to hold it all together. Biochar, which is essentially the charred remains of heated wood chips with no oxygen around, rounds out the mix, filling in for the need to use Portland cement. No more massive kilns burning fossil fuels and producing CO2. When the printer squirts out this binder, an acrylamide chemical, it starts a chain reaction known as frontal polymerization. As the nozzle heats it up, it ignites the whole mix, bonding the particles together one layer at a time. Nicolas Gonsalves was the one who led the experiment that showed the mix gains 3 megapascals of strength the moment it hits the air, which is more than enough to stack walls up high or arch over a doorway without needing a single prop.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000...

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 Mini 3D printers make...

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 Mini 3D printer takes care of all the calibration processes automatically,...

The speed at which this substance sets is game-changing since typical concrete takes so long to form. Builders pour a slab one day and then cross their fingers for 28 days before it can sustain weight; normally, they must install wooden and steel forms in the meanwhile. Roach’s team discovered that their material had 17 megapascals of strength for residential use in three days and 40 megapascals in eight to ten days. In one experiment, they printed a freestanding overhang that did not shift an inch, even when placed near a dummy window.

One of the other benefits to this new combination is the environmental impact. Cement plants alone are responsible for 5 to 8% of the world’s carbon emissions because of all the heat and gas that’s produced when limestone is broken down. This new mix avoids all of that drama. Hemp grows fast and absorbs CO2 from the air as it grows tall; biochar stores CO2 indefinitely, kind of like a sponge in the atmosphere. When it comes to the materials themselves, they simply sit in piles around the world until someone decides to use them. Roach’s team was able to obtain all of the materials required for the tests locally, reducing transportation emissions, and they also employed a low-heat technique that doesn’t require the use of fossil fuels.

Printing requires a machine-friendly substance, which this one does without fanfare. Extruders hum along, laying down precise ribbons that fuse on contact and do not droop or spread, clogging the system. The hemp strands thread through like natural rebar, avoiding cracks, and the biochar inhibits moisture from penetrating too deeply. Gonsalves conducted print after print, changing ratios until the flow remained smooth and the bonds tightened. One test spanned a gap the width of a doorframe, with the new curvature holding strong while layers piled on below. Such control allows for curved facades or elaborate supports that would take carpenters days to carve, but which a robot arm can do in hours. The arrangement is based on current 3D printers, such as the large frames found on job sites, but it runs without the usual pauses.

[Source]