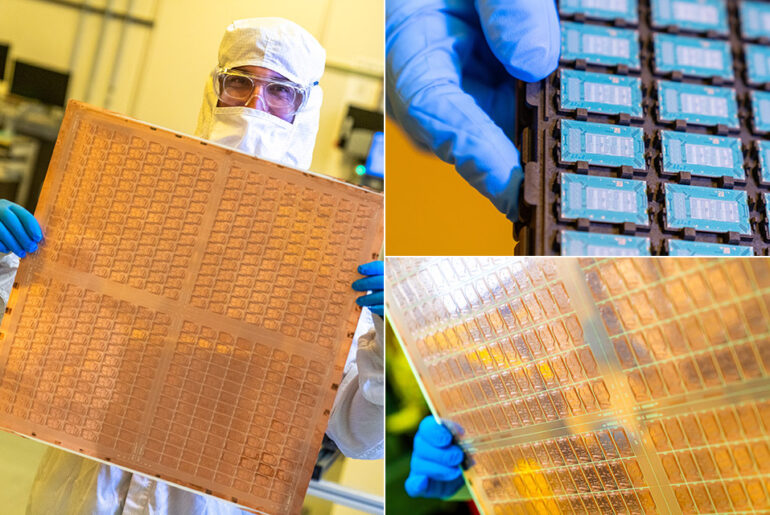

Intel introduces one of the industry’s first glass substrates for next-generation advanced packaging, enabling the continued scaling of transistors in a package and advance Moore’s Law to deliver data-centric applications. Why glass? It offers distinctive properties such as ultra-low flatness and better thermal and mechanical stability, thus providing much higher interconnect density in a substrate.

Have much higher interconnect density enables chip architects to create high-performance chip packages for data-intensive workloads such as artificial intelligence (AI) and Intel is on track to deliver complete glass substrate solutions to the market in the second half of this decade. Plus, glass substrates are capable of handling higher temperatures, while offering 50% less pattern distortion, and they have ultra-low flatness for improved depth of focus for lithography.

- Powerful Productivity: 11th Generation Intel Core i3-1115G4 Dual Core processor delivers unmatched speed and intelligence, enabling impressive...

- Visibly Stunning: Experience sharp details and crisp colors on the 15.6" Full HD IPS display with 82.58% screen-to-body, 16:9 aspect ratio and narrow...

- Ergonomic Typing: Ergonomically designed hinge lifts the keyboard for comfortable typing, improved cooling, and a better sound experience.

After a decade of research, Intel has achieved industry-leading glass substrates for advanced packaging. We look forward to delivering these cutting-edge technologies that will benefit our key players and foundry customers for decades to come,” said Babak Sabi, Intel senior vice president and general manager of Assembly and Test Development.