Researchers have created a machine that could change the way we respond to natural disasters. Kumagai Gumi of Japan, Tsukuba University, Nara Institute of Science and Technology, and ETH Zurich in Switzerland have built a giant robot hand with an AI-driven excavating system that will bring precision and safety to areas where human workers are at risk.

Flooded riverbeds, eroding cliffs and tangled debris require tools that can take a beating and still work. The robot hand is the result of the CAFE (Collaborative AI Field Robot Everywhere) project, a 5 year project funded by Japan’s Cabinet Office and Japan Science and Technology Agency. The researchers at ETH Zurich, who are experts in soft robotics, designed it to softly grab fragile objects, which is perfect for navigating the unpredictable rubble of a disaster area.

- Build your own awesome, wearable mechanical hand that you operate with your own fingers.

- No motors, no batteries — just the power of air pressure, water, and your own hands!

- Hydraulic pistons enable the mechanical fingers to open and close and grip objects with enough force to lift them. Every finger joint can be adjusted...

The hand accomplishes this by changing its grip to the shape and fragility of the object utilizing both smart sensors and flexible materials. Pneumatic actuators, which are essentially air-powered muscles, allow the fingers to flex and change in real time based on feedback from pressure sensors in the palm as well as fingertips. During the Tsukuba demo, the hand picked up everything from soft foam blocks to jagged metal fragments, and showed it can switch from featherlight to solid grips on the fly.

The CAFE project has a 3 ton weight limit, so the hand and apparatus can be taken to inaccessible areas like mountain valleys where landslides have blocked waterways. The main focus of the project is on river obstructions, also known as natural dams. When heavy rains or earthquakes cause cliffs to fall, rivers can back up and pose flood danger to entire communities. Historically, laborers have risked their lives to build drainage pumps or clear debris by hand as seen after the 2004 Niigata-Chuetsu earthquake. The giant robot hand, on top of a construction robot, is meant to take on those threats by precisely removing bottlenecks while keeping humans safe.

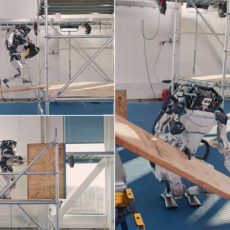

Kumagai Gumi, a Japanese construction company, brings practical expertise in heavy machinery while ETH Zurich contributes cutting edge robotics research. Tsukuba University and Nara Institute of Science and Technology round out the team and focus on integrating the hand with AI systems that make it more than just a tool. The hand’s ability to work in chaotic environments comes from its synergy with an automatic excavation AI also unveiled at the Tsukuba event. The researchers at Nara created this AI using a technique called Sim-to-Real reinforcement learning. It trains in virtual simulations to master digging tasks, before applying that expertise in real world situations.

It moved around a simulated disaster site, finding and removing hidden objects as it adjusted its approach based on obstacles. This is not a pre-programmed process, it learns and adapts on the fly, deciding how deep to dig and how much force to use. The CAFE project aims to reach Technology Readiness Level (TRL) 5 by the end of the project in November 2025. The August 2025 demo was TRL 4 and it showed the basic functionality in a controlled environment. By November 2025, they will be closer to real world deployment.

[Source]