Photo credit: David Baillot/UC San Diego Jacobs School of Engineering

Engineers at the University of California, San Diego have managed to create a thin layer of material that turns your run of the mill soft robots into agile explorers. These vine robots can stretch and twist through spaces that would be way too small and fiddly for bigger machines, just like a snake slithering through grass.

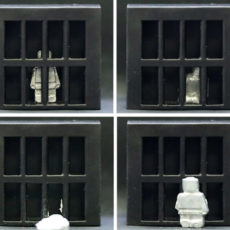

The vine robots start off tiny – they’re only 3-7mm across and 25cm long – but they move forward by basically turning their outer layer inside out from the front, much like putting a sock on. This clever trick stops the body from getting stuck against walls and reduces the wear and tear on the robot in tight spaces. Previous versions could only stretch straight out, but they still struggled to bend around corners.

- LEGO SET FOR ADULTS – The WALL-E and EVE (43279) building set offers adults 18 years old and up an immersive construction challenge featuring...

- 4 DISNEY PIXAR CHARACTERS – Builders can create iconic robots WALL-E, EVE, M-O and Hal from the hit movie—each with authentic functionality like...

- MINDFUL BUILDING EXPERIENCE – This detailed construction set lets builders practice advanced construction techniques for an immersive and relaxing...

The actuators in each robot’s skin are made from liquid crystal elastomer, which is basically super-strong yet super-flexible. These strips of elastomer are slotted into key positions around the body, so they can fold up without adding any bulk to the robot, and they’re powerful enough to pull the shape where needed. By applying a bit of heat, the elastomers shrink, pulling one side shorter than the rest. A quick jolt of current from the flexible wires underneath heats them up to the right temperature, allowing the researchers to precision-control the actuation. There are dozens of these pairs all around the length and circumference of the robot, which all work together to make the robot lean left, right, up or down on command.

Photo credit: David Baillot/UC San Diego Jacobs School of Engineering

And then there’s the air pressure system that really drives the whole operation. By applying a bit of air pressure inside the hollow body, the researchers can make the robot grow longer. Take the pressure off, and the tube softens up, making it easier for the robot to twist and turn. But crank up the pressure and everything stiffens up, so the robot just keeps going straight.

The researchers were able to find the perfect combination of heat and air shifts to get the robot moving and twisting. They found that by combining the two, they could get the robot to snap into place and hold its shape much faster and more effectively than using either system on its own.

Photo credit: David Baillot/UC San Diego Jacobs School of Engineering

One test they ran involved sending a robot through a clear plastic model of the aorta, the big curve where blood splits out to the body. It was able to twist over 100 degrees every second, and it even managed to fit into side paths without getting stuck. Even when the gaps were as small as half the width of the robot’s own body, it was still able to move just fine. They even attached a pinhead camera to the end of it, and the view it gave was incredibly detailed – something that would have been impossible for a human to reach with a normal instrument.

In another experiment, a robot was sent into a workshop set up to mimic a jet engine. It had to navigate around dummy turbines and fuel lines, which is a bit of a maze even for a human to crawl through. Along with its camera, the robot was on the hunt for cracks and deposits in the narrow crevices that a borescope on a stick just can’t reach. With this type of inspection, you can identify problems before flights become a genuine risk, saving significant time.

Photo credit: David Baillot/UC San Diego Jacobs School of Engineering

It’s all about shrinking down now; the robots are currently pencil-lead thin, but to reach their full capability, they’d need to be less than a millimeter thick. With the ability to transmit a signal or having some onboard smarts, the tether that connects them to a central hub may be severed, allowing them to crawl around independently. When it came to looking at this from a medical standpoint, the National Institutes of Health provided valuable funding, and the Beckman Foundation pushed them to develop new materials. With each layer they peel back, they reveal more territory they’ve covered, bringing these quiet tiny crawlers closer to regions that were previously considered to be completely off-limits.

[Source]