A $60 second-hand steel-frame bike, stripped to the bone and rebuilt with 3D printed PLA gears sounds like a recipe for disaster. But YouTuber Well Done Tips took this crazy idea and rode it – literally – at 20 km/h and proved that plastic can punch above its weight.

Well Done Tips starts with a local market find: a weathered steel-frame bike for pocket change. After a good wash to remove years of grime, the bike is torn down. Shifters, cables, rear derailleur, chain and front chainrings are removed, leaving a blank canvas. A special cassette removal tool helps with the old drivetrain, and the pedal assembly comes off with ease, thanks to the bike’s old, but simple, one piece crank system.

- Unleash Your Creativity: The Perfect Companion for Beginners and Experts Alike. The AD5M combines brand-new technology and superior craftsmanship to...

- Achieve Perfect Prints with Ease: The AD5M is equipped with a fully automatic one-click leveling system that precisely measures the nozzle-to-build...

- Core XY All-Metal Motion Structure: The AD5M features a durable, innovative design that ensures high-speed printing without compromising quality. Its...

To support the custom drivetrain, Well Done Tips constructs a base from a 10×40 mm steel flat bar found in a garbage pile. An angle grinder is used to form the bar so it fits around the bike’s kickstand mount and bottom bracket. A 3 mm steel piece is offset and tack welded prior to permanent welding. To counter flexing, a 30×10 mm rectangular steel tube is welded beneath the seat stay while carefully navigating the rear wheel spokes.

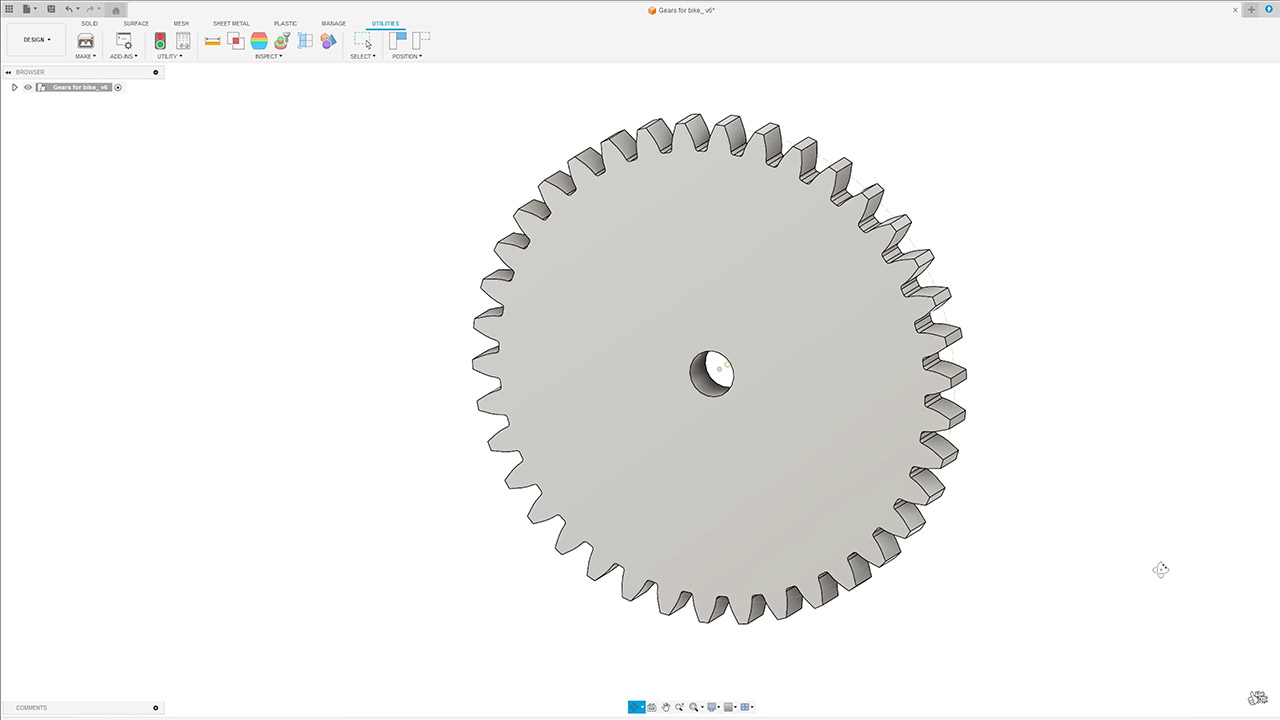

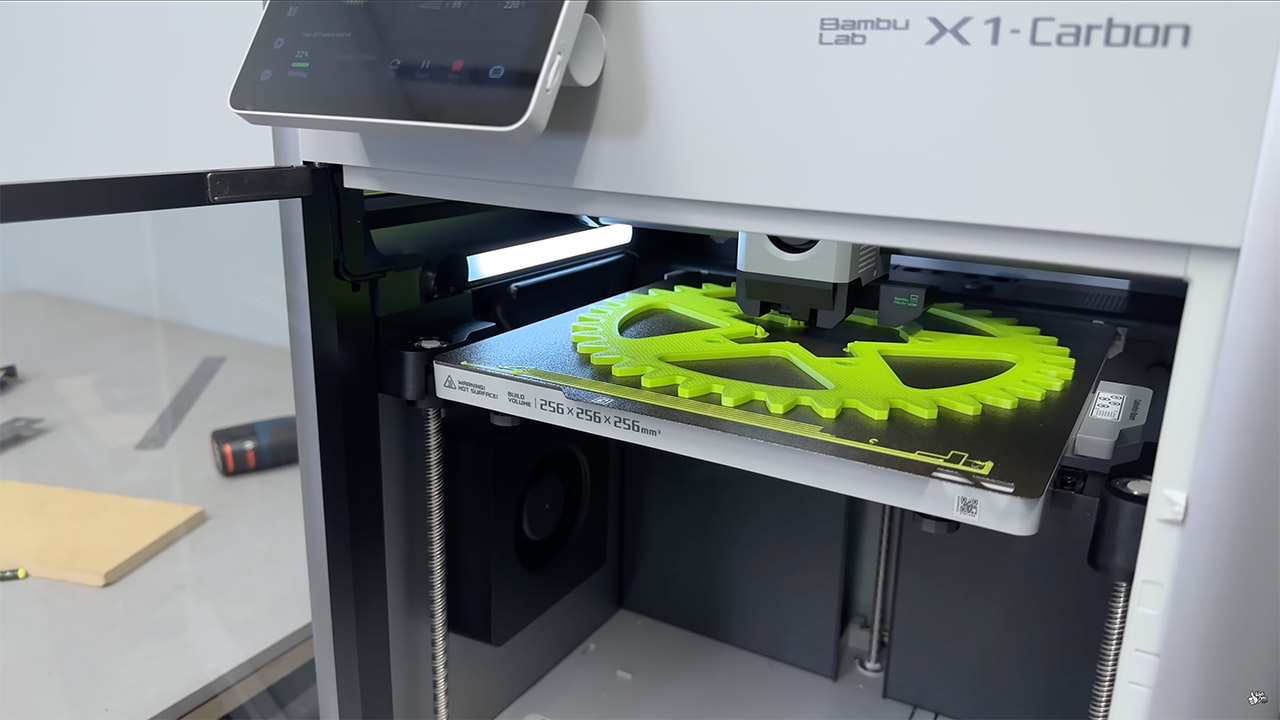

The gears were created in Fusion 360 using the spur gear add-in, and with only a few parameters (tooth count, gear thickness, and center hole diameter), the software produces perfect spur gears. The main drive gear is a 38-tooth monster manufactured in PLA using a Bambu Lab X1 Carbon printer. The size is simply limited by the printer’s bed. For the rear wheel, an 18 teeth gear is printed with 6 perimeters and 40% infill for strength, reinforced with a metal sprocket from the bike’s original cassette. Three 16-tooth idler gears bridge the gap, allowing the pedals and back wheel to rotate simultaneously.

The idler gears contain two 608 RS bearings (22×7 mm with an 8 mm inner hole) and must be precisely placed. Well Done Tips reduces metal spacers to 6 mm for a tight fit. They hold the spacer using an M8 Allen bolt and nuts, then use a marker to color the bolt to indicate grinding progress. The bearings are hammered in with a hammer and socket, and they spin smoothly with fresh grease. To place the gears, one is left with only one bearing for improved visibility, and a 1 mm backlash is eyeballed to prevent binding. A drill press creates 7 mm holes perpendicular to the steel bar, tapped for M8 bolts, and secures the gears to the steel bar with stainless steel button head bolts for a clean finish.

The exposed metal is primed, and a custom blended paint is put to the frame extension. This isn’t a perfect match, but after several clear coats and drying, it’s passable. The final assembly consists of reinstalling the back wheel, mounting the gears, and greasing the bearings. On the test ride, the bike easily reaches 20 km/h, and the PLA gears meet predictions of instant failure. A squeak appears under strong pedaling, most likely due to dry gears grinding, while gentle pedaling maintains everything smooth and quiet.

[Source]