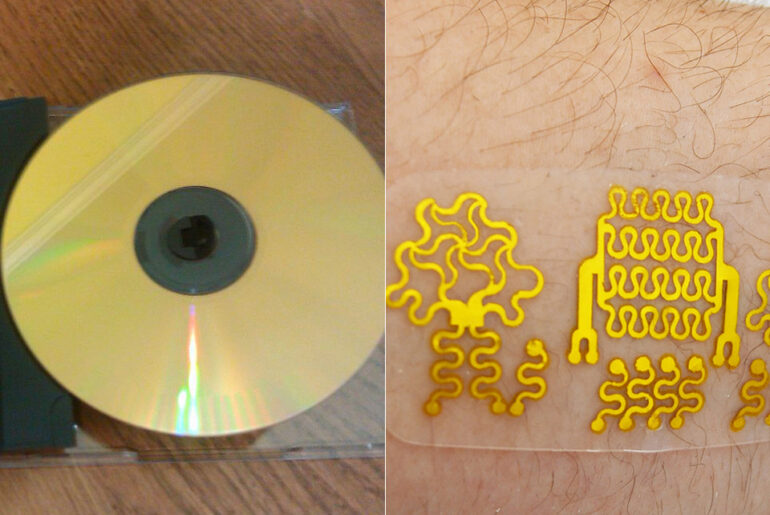

Researchers at Binghamton University have devised a method for turning old compact discs into flexible biosensors that can be fabricated in just 30-minutes. This method would separate the thin metallic layer of a gold CD from the rigid plastic before fashioning the material into sensors to monitor electrical activity in human hearts and muscles as well as lactose, glucose, pH and oxygen levels.

These wearable sensors would then be able to communicate with a smartphone using Bluetooth. The fabrication process would only take 20-30 minutes, all without releasing toxic chemicals or needing expensive equipment. Best of all, it costs only around $1.50 per device to make. This would be a sustainable approach for upcycling electronic waste and provide an advantageous research-based waste stream that does not require cutting-edge microfabrication facilities. You may even be able to fabricate these at home, using something like the Prusa MINI 3D printer in the near future.

- WHY IPAD — All the essentials in the most affordable iPad, with a beautiful 10.2-inch Retina display, powerful A13 Bionic chip, and an Ultra Wide...

- IPADOS + APPS — iPadOS makes iPad more productive, intuitive, and versatile. With iPadOS, run multiple apps at once, use Apple Pencil to write in...

- FAST WI-FI CONNECTIVITY — Fast Wi-Fi keeps you connected at home, work, school, or wherever you go with your iPad.

When you pick up your hair on your clothes with sticky tape, that is essentially the same mechanism. We loosen the layer of metals from the CD and then pick up that metal layer with tape, so we just peel it off. That thin layer is then processed and flexible,” said Ahyeon Koh, Assistant Professor from the Department of Biomedical Engineering at Binghamton University.