Matt of Polymatt decided to create a 3.5-inch floppy disk from scratch simply because he could. His journey demonstrates problem solving, science, engineering, and a touch of obstinate curiosity.

He started by tearing apart a real 3.5-inch floppy disk to see what’s inside, and discovered a thin flexible PET film coated with a magnetic layer, a central hub for spinning as well as a fabric lining to protect / clean the disk. Some parts like the protective flap or write-protect switch he deemed non-essential for his proof of concept. His goal was clear: recreate the shell, the magnetic media and make it spin in a drive to read and write data, all with tools and materials available to any hobbyist.

- Ultra-fast Speeds: Designed for creators, students and PC gamers, this matte blue external SSD delivers fast data access with up to 2,100MB/s read...

- Built to Last: Perfect for travel and all types of weather with IP65 dust and water resistance. Plus, it's drop resistant up to 9.8 ft (3 metres)....

- Broad Compatibility: External drive connects effortlessly with Windows, Mac, iPad Pro, Chromebooks, Android, Linux, PS4, PS5, and Xbox via USB-C and...

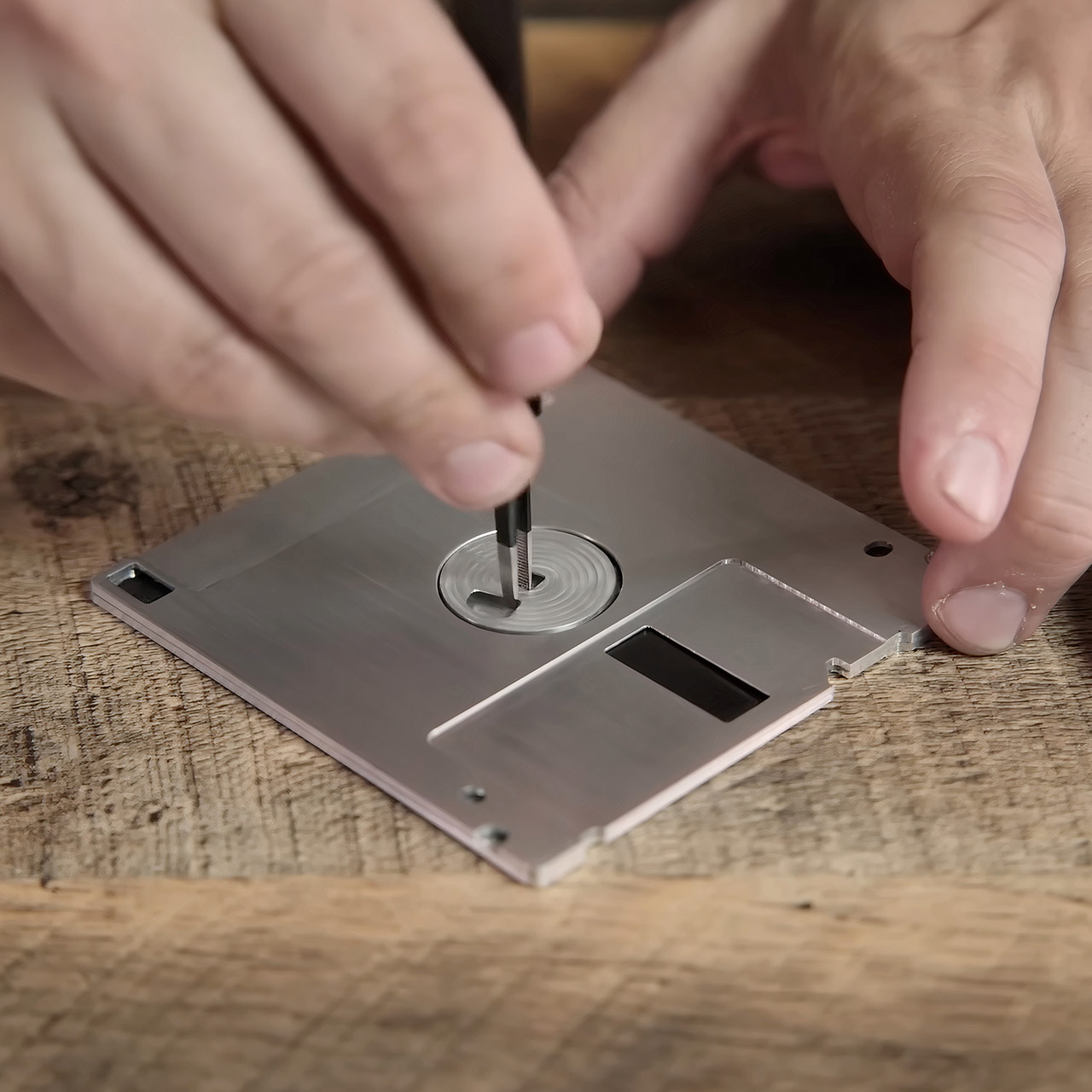

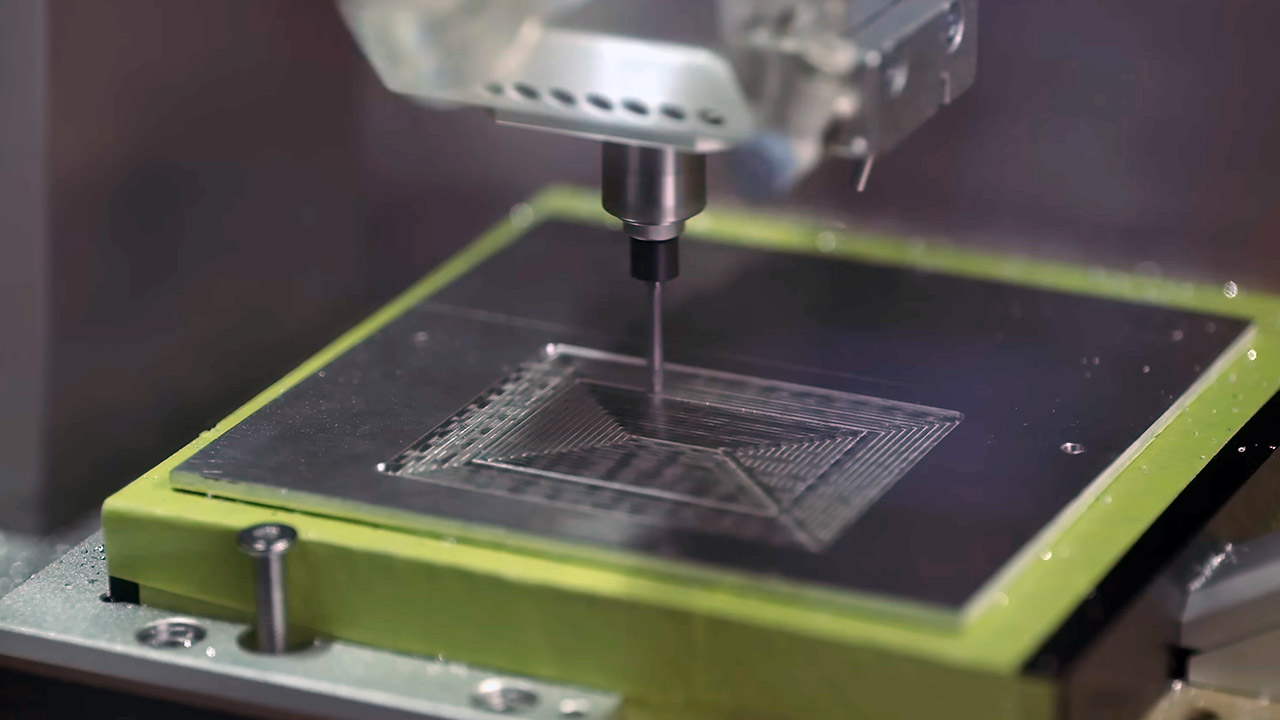

Creating the shell was the first hurdle. Matt turned to his new desktop CNC machine, the Carvera Air from Makera, to mill the disk’s enclosure from 3 mm aluminum plates. He measured an original disk with calipers, modeled every dimension in Shapr3D software to ensure precision. Milling such a thin shell (1.6 mm per side) was a gamble but the CNC’s precision, aided by a tape-and-superglue method to secure the aluminum, delivered. After milling he sanded the surface for a brushed aluminum finish, creating a sleek almost futuristic shell that outshone the neon plastic originals. A small oversight (missing two alignment holes) caused the drive to reject his first attempt but a quick return to the CNC fixed that.

The real challenge was the magnetic media, meaning that Matt needed to coat a PET film with a magnetic layer thin enough to rival commercial disks which are about 2 microns thick when dry. He sourced PET film and cut it precisely using the Carvera Air’s optional 5W laser, after an attempt to make a drag knife failed due to alignment issues. To ensure the film was perfectly flat he heated it to 70°C under a weighted glass panel in a 3D printer, relieving internal stresses without deforming it.

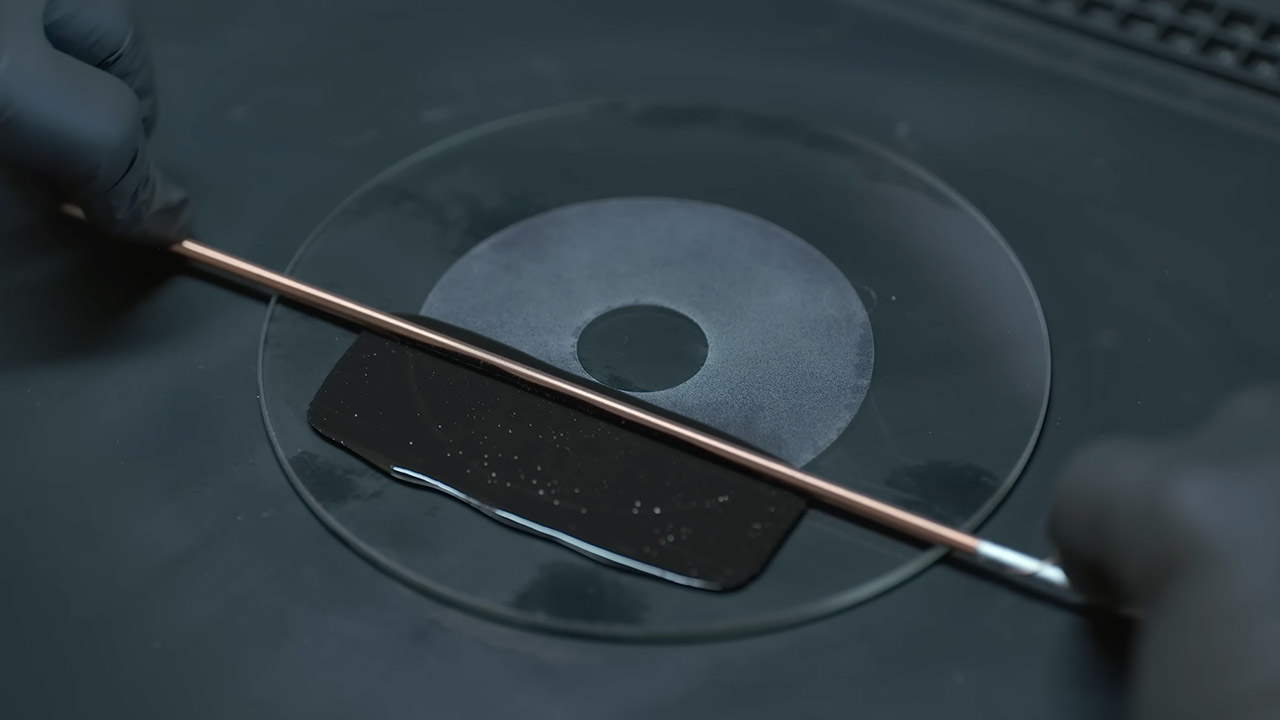

Matt found the Mayer rod, a steel rod wrapped with copper wire, which creates tiny gaps to apply a consistent, micron-thin layer of liquid, to help him coat the film. His magnetic solution was a suspension of black iron oxide powder in a binder of polyvinyl alcohol (PVA), isopropyl alcohol, glycerin for flexibility, and Tween 20 to keep the powder evenly dispersed. Getting the ratios right took multiple tries, with each batch degassed to remove microbubbles. He scuffed the PET film with 2000-grit sandpaper and applied a “poor man’s corona treatment” with a flame to make it less hydrophobic, so the coating would stick. After applying the suspension with the Mayer rod, he dried it in a controlled vacuum to get a 5-6 micron layer—thicker than commercial disks but thin enough to test.

Matt then glued the coated PET film to a central hub with minimal superglue to avoid strain, lined the aluminum shell with soft polyethylene pads (used for cleaning camera lenses), and sealed it with double-sided tape. His first test was a failure—the drive wouldn’t spin. After fixing the alignment holes and making sure the hub was exact, the disk finally spun. But when he tried to read it, the drive’s head peeled off the magnetic coating, revealing its fragility. Undeterred, Matt refined his approach. He switched to a thinner 42-gauge wire for the Mayer rod, tweaked the binder for better adhesion, and tested alternative binders like UV-curable resin (which failed because the iron oxide blocked UV light) and two-part epoxy (too viscous).

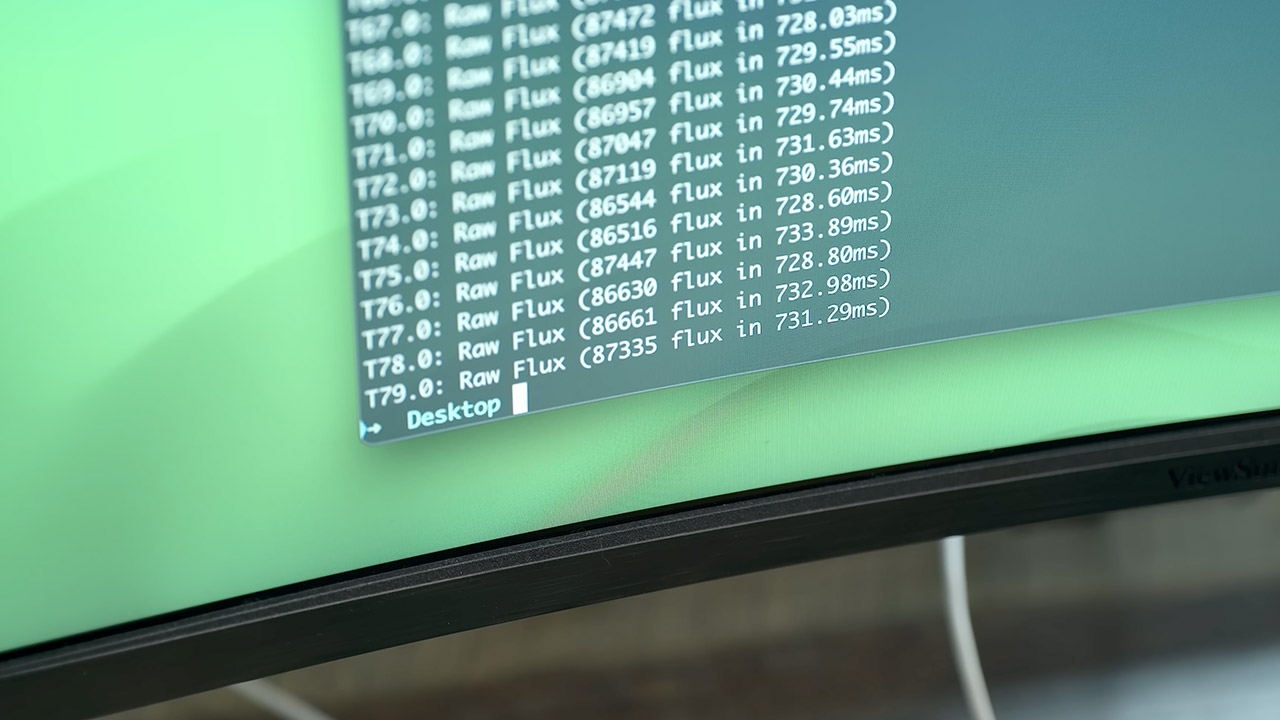

Using the Grease Weasel, Matt visualized the magnetic flux transitions on his disk—tiny pole-to-pole shifts that encode data, during the final test. The disk looked good, with visible magnetic patterns, but writing data was another story. An unverified write attempt failed, but after some troubleshooting, he saw track sectors and raw data in the HXC Floppy Emulator software.

[Source]