RCLifeOn started with a surfboard, added fans that blow air backwards to move it forward and soon he was gliding without a drop of gas. Now he’s added a mechanism that directs the force of those fans exactly where you want.

Electric surfboards work because they borrow from remote-control planes and boats. Mount one or more ducted fans – those enclosed propellers that suck in air and blow it out the back – onto the back of a lightweight board. Wire them to electronic speed controllers that ramp up the power smoothly. Strap a pack of lithium-ion cells underneath, big enough to last for long sessions but balanced to keep the nose up. Grip a handheld remote with joysticks for throttle and direction and you’re off, planing across the surface at speeds that rival a jet ski. Riders steer by shifting their weight, just like on a wave with a regular board. Lean left and the board banks that way; twist your hips and it pivots.

- No Registration Needed - Under 249 g, this drone with camera for adults 4K does not require FAA registration or Remote ID for recreational use. Visit...

- 4K Ultra HD & 3-Axis Gimbal for Cinematic Quality Shooting - Capture stunning moments in any light—sunrises, sunsets, and night scenes with...

- 38kph (Level 5) Wind Resistant - This drone for adults has a stable flight even in Level 5 winds. Brushless motors enhance power and allow takeoff at...

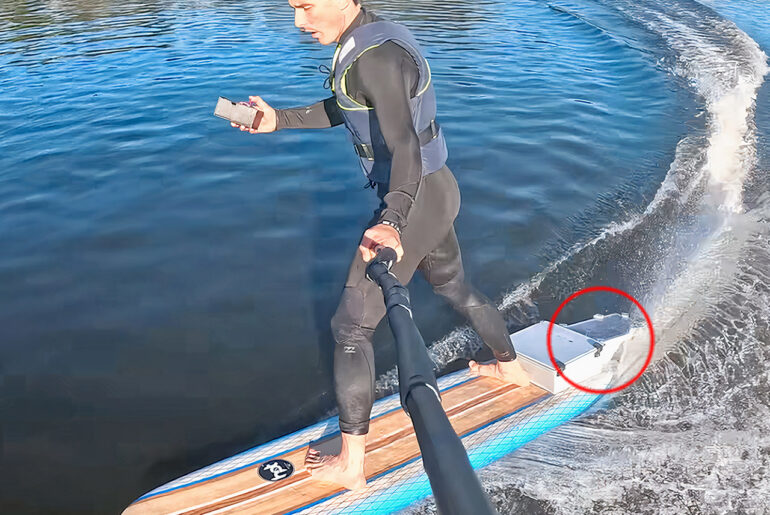

Those ducted fans produce a steady stream of force but until now it always pointed straight back. The new twist routes that force through adjustable nozzles fitted right behind each fan. Picture flat panels that pivot on hinges, like louvers on a vent, but beefed up to withstand the rush of air and spray. Large servos – those reliable motors from the model-airplane world – drive the nozzles side to side and up and down. Each servo has enough torque to snap the panels into place against the pushback, holding steady even at 20mph.

RCLifeOn created the unique nozzles out of tough plastic composites, shaping them to direct airflow without sacrificing power. They were fixed snugly against the fan outlets, with the edges sealed with rubber gaskets to prevent leakage, and the servos were connected by robust aluminum arms. All of this was linked into the main controller board, which now receives the remote’s inputs and translates them into precise angles—5 degrees left for a mild curve, 15 for a strong carve.

Control is still in your hands, but the system makes it more precise. Squeeze the throttle on the remote and the fans spin up. Nudge the stick left and the nozzles tilt to push water right, swinging the tail around.

[Source]