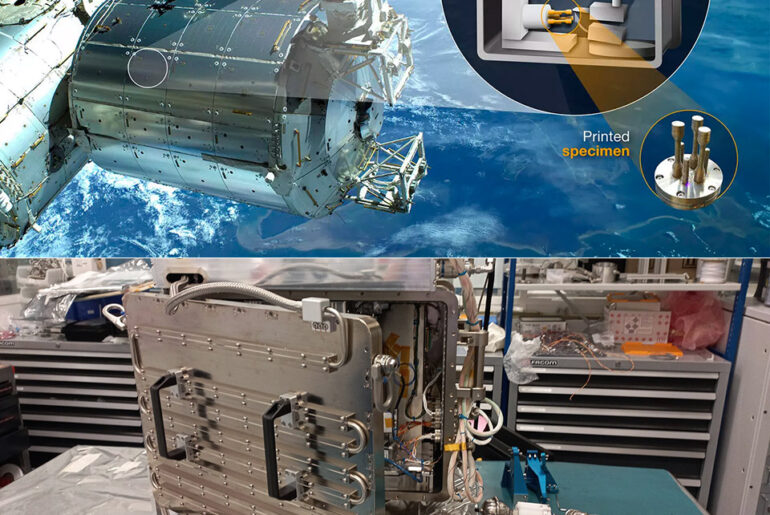

The world’s first metal 3D printer for space, developed by Airbus and the European Space Agency (ESA), is officially headed to the ISS. One big challenge was shrinking the size of the 3D printer down to the size of a washing machine, as metal versions traditionally require at least a 10-meter laboratory.

This metal 3D printer is nestled in a sealed metal box, which acts like a safe. Why? The melting point of metal alloys compatible with this process exeeds 1,200°C degrees compared to around 200°C degrees for plastic. Printing with metal aboard the ISS will help improve the understanding of the quality of metal printing in orbit and provide valuable insights into operating a metal 3D printer in space.

- Resume Printing Function: no worry to the immediate power outage or electric circuit error, Ender 3 has the ability to resume printing even after a...

- Creality Ender 3 3d printer, it is the most basic 3d printer model, more students and beginners can learn the 3d printer by this model, it can help to...

- Advanced Extruder Technology: Ender 3 upgraded extruder greatly reduces plugging risk and bad extrustion; V-shape with POM wheels make it move...

The metal 3D printer will bring new on-orbit manufacturing capabilities, including the possibility to produce load-bearing structural parts that are more resilient than a plastic equivalent. Astronauts will be able to directly manufacture tools such as wrenches or mounting interfaces that could connect several parts together. The flexibility and rapid availability of 3D printing will greatly improve astronauts’ autonomy,” said Gwenaëlle Aridon, Airbus Space Assembly lead engineer.