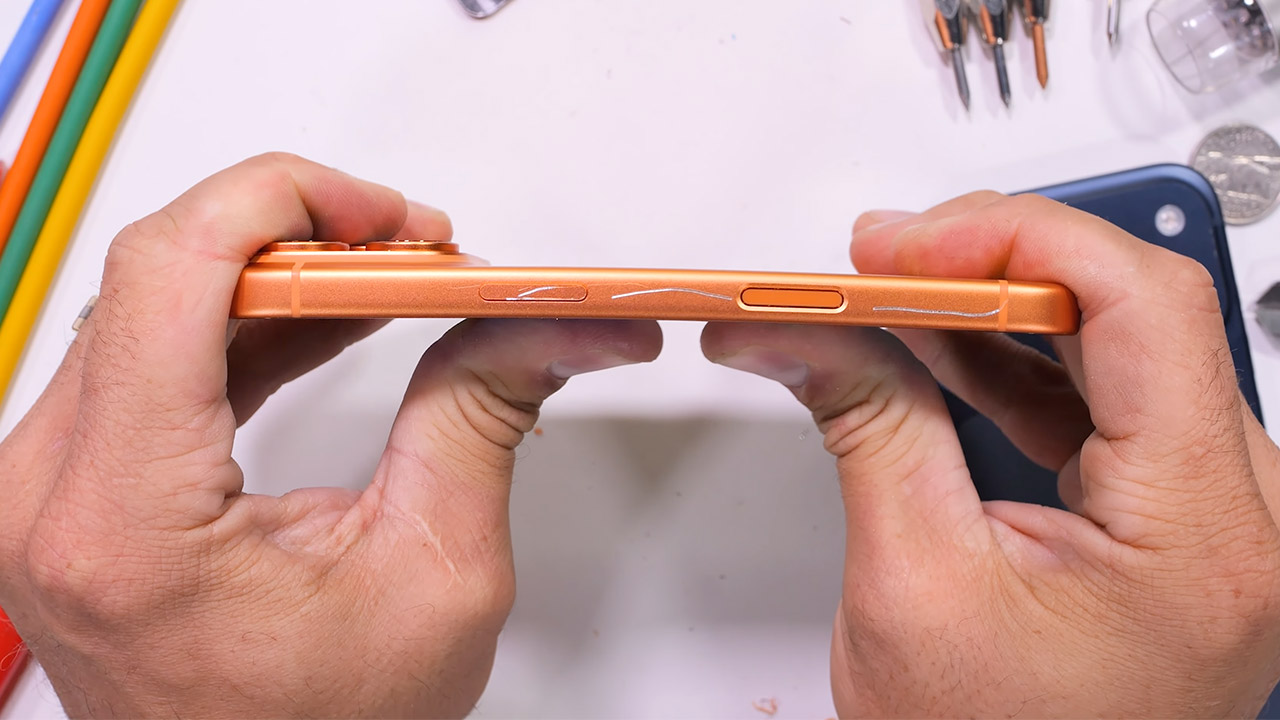

Zack Nelson has made a career out of torturing high-end gadgets and his latest video tests the iPhone 17 Pro with reckless abandon. This phone comes out of the box with titanium edges and an aluminum unibody wrapped in anodized colors like Cosmic Orange and Deep Blue. Fans are already complaining that it scratches too easily, calling it the “Scratch Gate” sequel no one asked for.

Nelson starts with a confession: as an Android user, he can’t help but love the iPhone 17 Pro’s design. The metal camera bump and seamless aluminum body are a welcome change from the glass sandwiches of the past, he says, but Apple has forgotten a basic truth about coatings. The anodized finish, the oxide layer that gives the phone its pop, has a Mohs hardness rating of 9—tough enough to withstand most everyday scratches and one step below diamond. To make it, Apple dips raw aluminum in an electric acid bath which creates a strong shell in seconds. Sharp corners however are the Achilles’ heel. With little metal to anchor the coating, those edges become powder kegs waiting for a spark.

- Touch-sensitive and capacitive button cover for seamless functionality

- Raised edges for screen and camera protection Military-grade via Extreme Protection Tech

- All-new revamped design with built-in kickstand for hands-free viewing

Nelson zooms in with a digital microscope to show the culprit: the camera plateau’s near vertical drop off which was machined without a single softening curve, chamfer or fillet. He believes this was a deliberate design choice for visual impact—those lines make the phone look like a work of art. The anodizing which is 2-25 microns thick (thinner than half a human hair) is durable on flat surfaces but peels off when the substrate is thin.

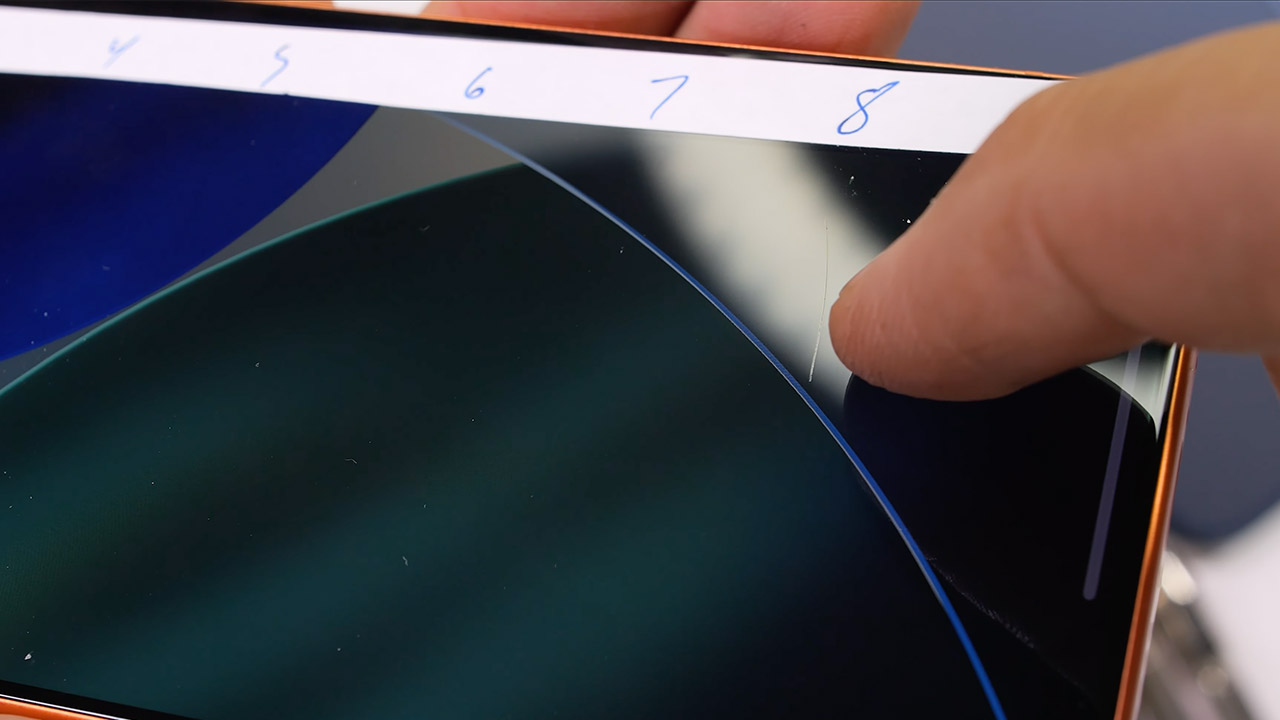

Aluminum is a 3 or 4 on the hardness scale, outlasts glass’s 5 or 6 in drop tests and when combined with Corning’s Ceramic Shield 2 on the front the phone can withstand marks from pick 6 or 7. Pick 8 leaves a scratch but the 6.3 inch, 3000 nit OLED display survives his flame test remaining stable after 30 seconds of direct torch exposure. The back is also beautiful with three 48 megapixel cameras (wide, primary and 4x telephoto) under sapphire crystal and a laser focusing module under glass. Even the textured glass patch around the Apple logo is scratch resistant and washes clean if it was never there.

Nelson simulates pocket risk with a quarter that grinds harmlessly against the phone’s flats, but at the camera plateau’s corner, the anodizing yields in a heartbeat, exposing raw silver aluminum beneath. Keys follow suit, their edges brushing off shielded zones as they carve a crater in the same unyielding lip. The damage is obvious under the microscope: vivid orange everywhere except the sheared edge, where the coating has calved off.

ISO and US military regulations require radii that are at least 10 times the anodizing thickness—roughly a quarter to half a millimeter—to allow the coating to hold adequately. Apple avoided both, which he attributes to design over engineering. This produces chips that are completely ornamental, never affecting functioning, yet erode the phone’s perfect exterior faster than titanium ever could. Previous models with rounded corners or glass backs avoided this physics dance, but the 17 Pro welcomes it.

![Spigen for iPhone 17 Pro Case, Tough Armor T MagFit [Camera Control Button] [Compatible with Magsafe] -...](https://m.media-amazon.com/images/I/41VX8ojshLL._SL160_.jpg)