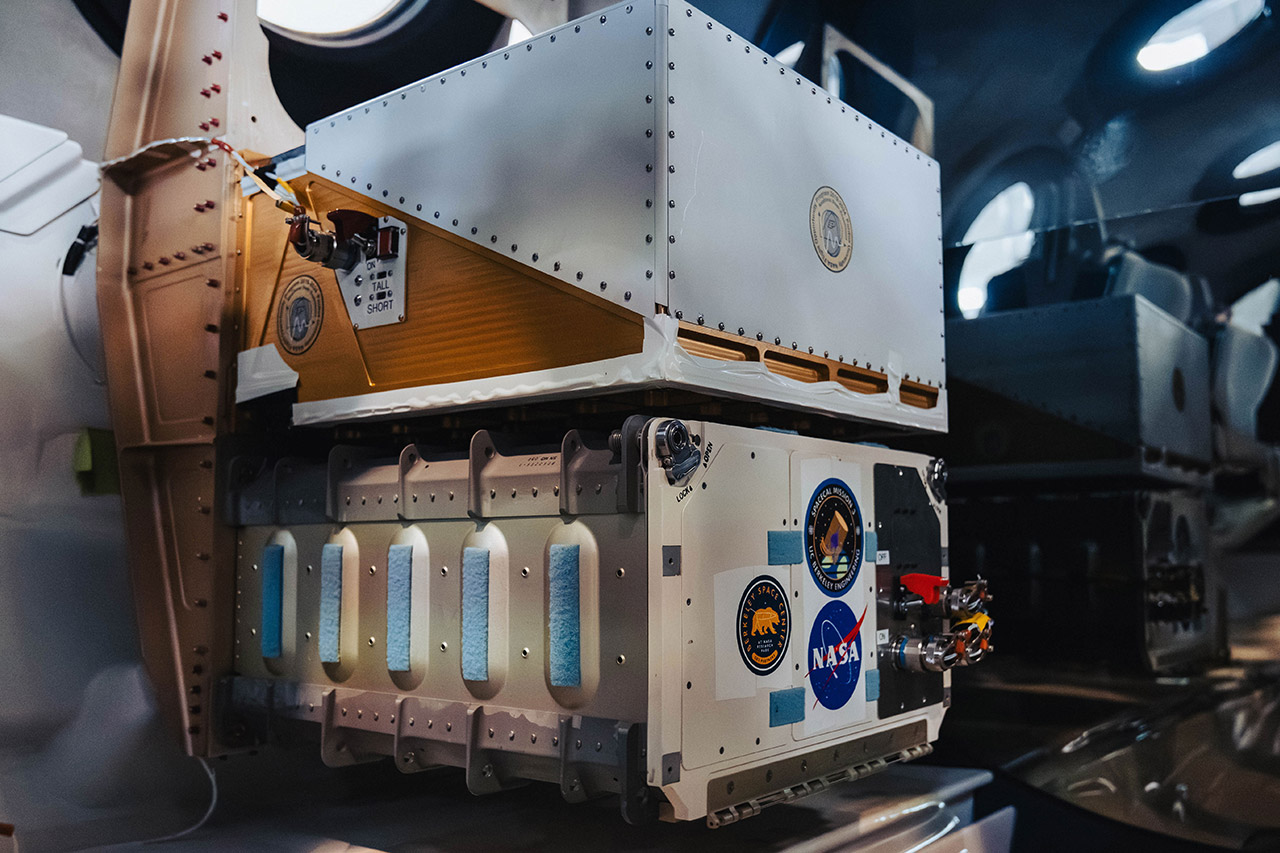

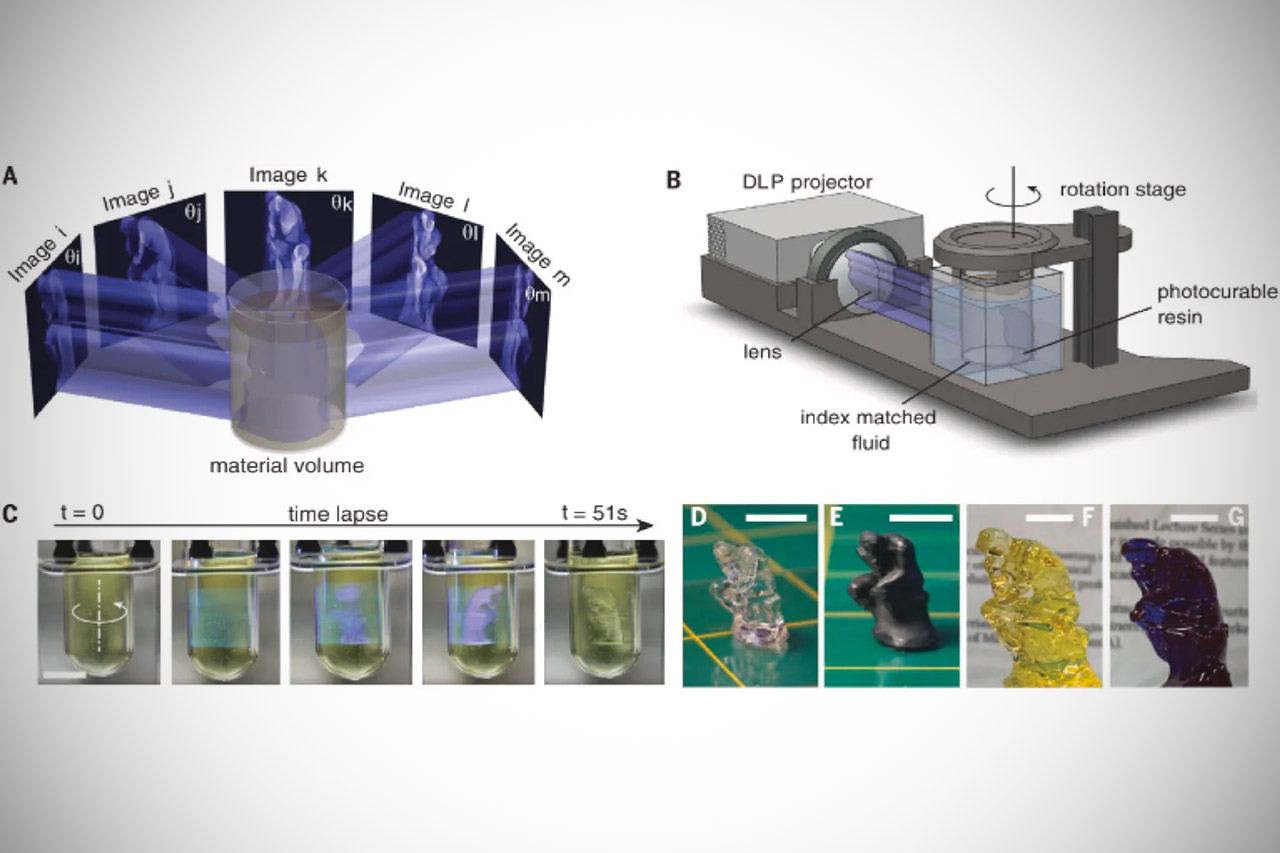

Berkeley researchers, led by Ph.D. student Taylor Waddell, sent their SpaceCAL 3D printer into space as part of the Virgin Galactic 07 mission. This next-generation microgravity printer spent only 140 seconds in suborbital space, yet managed to autonomously print and post-process a total of four test parts, including space shuttles as well as benchy figurines.

It created these figurines using a liquid plastic called Polyethylene Glycol Diacrylate (PEGDA), which is hydrophilic, elastic and can be customized to include a variety of biological molecules. What sets SpaceCAL apart from standard 3D printers is its incredible speed, enabling it to create parts in as little as 20 seconds. This means astronauts could potentially print parts quickly in an emergency and on demand, thus eliminating the need to bring a multitude of spare parts on long-duration space missions.

- Reliable Printing with Ideal Build Size: ELEGOO Neptune 3 Pro offers a standard 225x225x280 mm/8.85x8.85x11 inch build volume, ideal for daily...

- Powerful Direct Drive Extruder: The Neptune 3 Pro features a dual-gear direct drive extruder with a 3:1 gear ratio, built from durable SUS303...

- Smarter Printing, Less Worry: ELEGOO Neptune 3 Pro includes 36-point auto bed leveling, making setup effortless while ensuring a perfect first layer....

SpaceCAL performed well under microgravity conditions in past tests aboard parabolic flights, but it still had something to prove. This latest mission, funded through NASA’s Flight Opportunities program and with support from Berkeley Engineering and the Berkeley Space Center, allowed us to validate the readiness of this 3D printing technology for space travel,” said Taylor Waddell, Ph.D. student at Berkley.

[Source]