Zac Builds removed the lid from a dusty old Sony PS3 and peered down at the two ancient chips that had been resting there for 15 years. The thermal paste beneath has long since become dust. He pulled up a hot-air gun and gently tugged on the GPU’s cover, which popped right off like an old rusted hubcap. In that instant, he knew that Sony had left a lot of power on the table, and Zac was about to cash in.

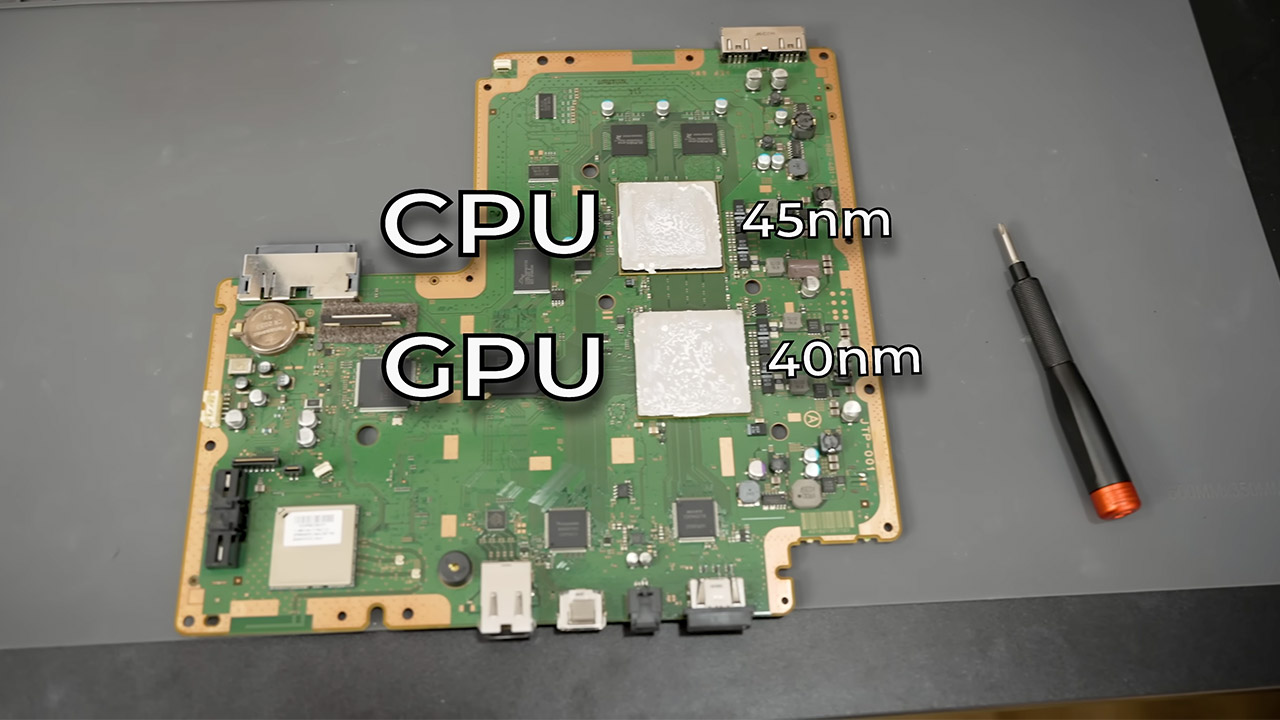

He chose the CECH-2501B, Sony’s last system that could still be hacked. It has smaller transistors, and half the power consumption of the cumbersome old 2006 model, yet the firmware remained wide open The 3D scanner runs for an hour and produces an extremely accurate digital twin of the motherboard, down to the breadth of a single hair. He designed two bespoke aluminum water blocks based on that scan, one for the Cell CPU and one for the RSX GPU, because their heights differ and they don’t want to share a single block.

- Model Number CFI-2000

- Includes DualSense Wireless Controller, 1TB SSD, Disc Drive, 2 Horizontal Stand Feet, HDMI Cable, AC power cord, USB cable, printed materials,...

- Vertical Stand sold separately

He then printed out some carbon-fiber nylon brackets using a Bambu Lab P2S and then baked them at 85 degrees for a whole day to make sure they wouldn’t sag under heat/pressure. For good measure, he slapped some copper heatsinks on top of each block in case the pump ever dies, so the chips stay alive. Then there’s those rather gentle bends in the soft PVC tubing as he’d snake it through the gutted shell, elbow fittings keep every single one looking nice, and a nice big 120 mm radiator slapped in where that old screaming fan used to live.

When idle, the GPU reaches 67°C using the usual fan configuration. But water cooling reduces that to a comfortable 40°C idle and 43°C flat out. That extra space is a blank cheque. He was able to tweak the firmware so that he could increase the GPU rate from 500 MHz to 750 MHz and the memory clock from 650 to 925 MHz, resulting in a great 50% increase in power without a single hiccup.

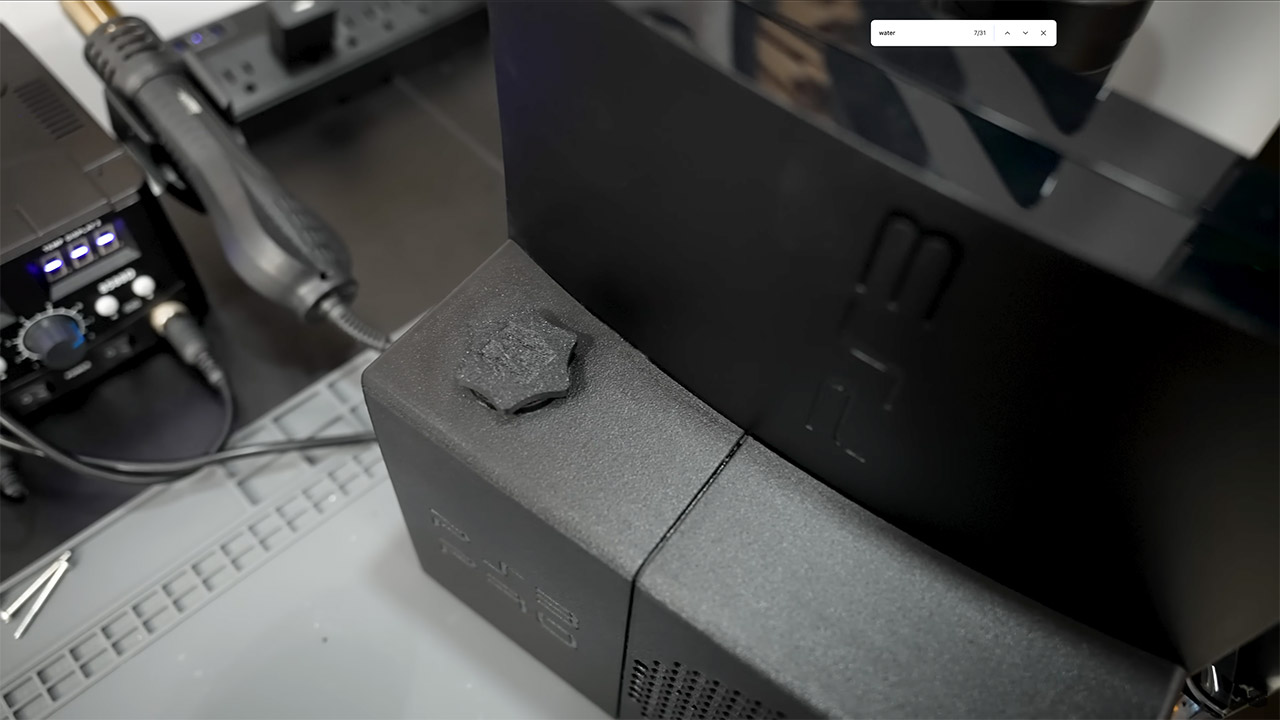

He also replaced the bulky old 5400 RPM hard drive with a silent terabyte SSD. So load screens, which used to take thirty seconds, now take only eight seconds to appear. And the whole thing now breathes through a new bespoke black top that he printed in two pieces and slapped on, complete with honeycomb vents and a screw-on fill port that looks factory-new.

Zac admits that having a water loop was perhaps overkill. A fresh layer of paste and a super quiet Noctua fan would have likely unlocked the majority of the speed we desired. But, truthfully, the water loop solved a question that no one else appeared to care about: how fast can a 2006 console run? And the solution is right in front of him on his desk, at a nice toasty 40 degrees, racing circles over every single one that left the factory as a brand new PS3.

He used the oscillating tool to cut the top shell, pushed the line out of a printed template, and then went in with a file to smooth off all the edges to perfection. You can still snap the replacement roof back into the original clips, ensuring that the console is ready for any future servicing. Overall, he completed the project in three weeks, with 48 hours spent simply waiting for the prints to dry, and one near-panic moment when the GPU lid snapped free as he was attempting to put the final pieces together.

[Source]