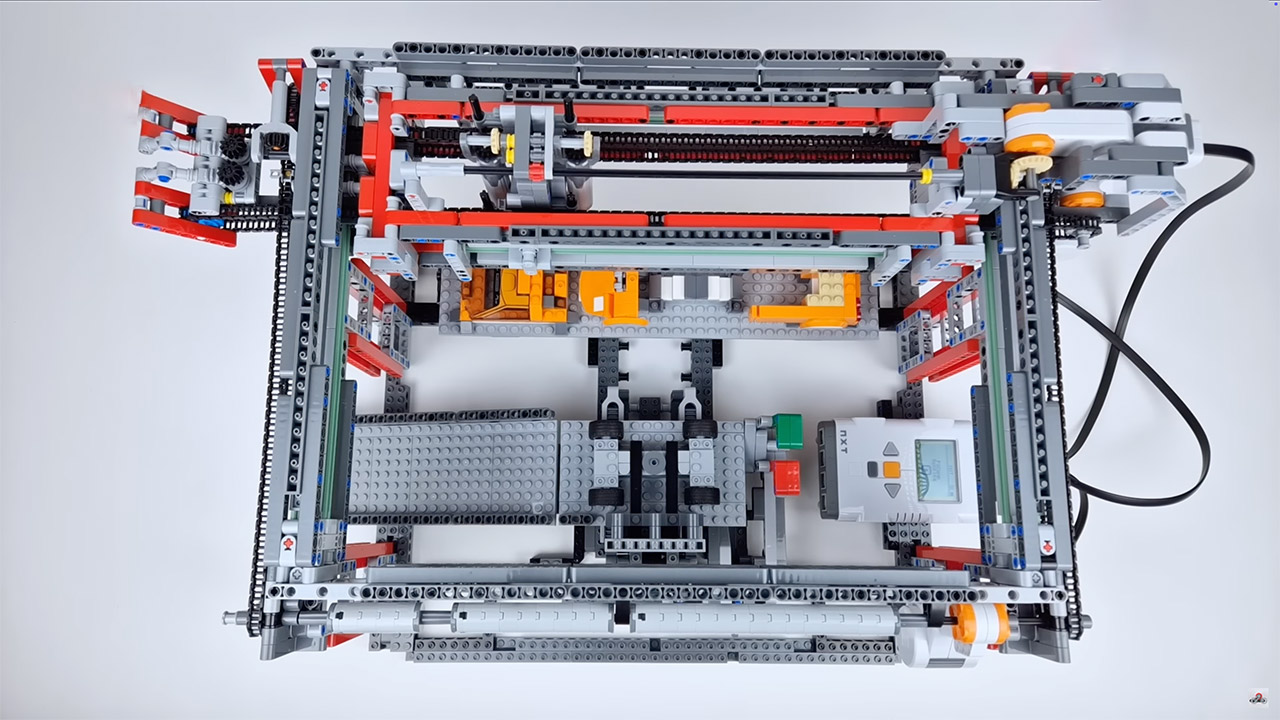

Banana Gear Studios has created something unique: a completely automated factory that precisely assembles LEGO cars. The build video shows a three-axis positioning system, a smart grabber mechanism, and a well planned sequence that brings a seven-part LEGO automobile to life.

The machine uses a 3 axis system to move a grabber with a lime green LEGO piece across side to side, front to back and up and down. Linear actuators provide the force to pick up and place parts with precision. Each car part from chassis to windscreen must align perfectly, even a fraction of a mm off and the grabber will miss. To achieve this the creator used long axles as rails with rollers to support the weight of the structure and smooth movement. Chains tensioned with a linear actuator eliminate backlash so the grabber hits its target every time.

- BUILD A HYPERCAR ICON – Car fans ages 9 years old and up can experience the thrill of race day with the LEGO Speed Champions Bugatti Centodieci...

- AUTHENTIC BUGATTI DETAILS – Young builders can recreate signature Centodieci elements, including the 5 round air intakes, horseshoe radiator grille,...

- BUILD, RACE & DISPLAY – Kids can stage epic hyper car showdowns with their Bugatti toy car—complete with a driver minifigure in racing gear—then...

Programming the factory involved mapping out the grabbers movements using a 3D coordinate system visualized as a grid where colored squares represent each position. A spreadsheet translated these coordinates into motor rotations, over 100 operations to assemble one car. To make it reliable the grabber does a “wiggle” motion, a quick square trace around each stud to align itself before pressing down. This is how humans assemble LEGO, sliding pieces until they snap into place. The result? A success rate from 20% to 97%.

The car itself is a simplified version of a complex LEGO model and breaks down into 7 parts: chassis, front wheels, rear wheels, engine, front body, rear body and windscreen. Each part sits on a pallet ready for the grabber to pick and place. The assembly platform is a nice feature, it has 2 prongs to hold the car in place during construction. The prongs are controlled by green and red buttons and retract to release the completed car which rolls down a ramp and out of the factory. The prongs thicker lower section align the chassis precisely and is locked in place by a lever mechanism to prevent any movement during assembly.

It wasn’t easy, as early tests revealed alignment concerns and the grabber was missing studs or inserting pieces incorrectly. Curved edges on the chassis prevented it from catching on the prongs. Although smaller gears reduced positional uncertainty by 33%, structural wobbling and initial misalignment remained an issue. The wiggle technique was a game changer.