Engineers at HTX Studio in China have reimagined throwing trash by creating a series of robotic trash cans that chase and catch flying rubbish, turning a boring task into an engineering and creativity show.

The problem was simple: cluttered workspaces with paper, bottles and wrappers everywhere, despite having bins. HTX’s solution was bold—bins that intercept trash mid-air and empty themselves. Two main challenges emerged: predicting where trash would land and moving the bin there fast. Their answer is a camera equipped, motorized bin that tracks objects and catches them.

Sale

EKO Mirage-T 50 Liter / 13.2 Gallon Touchless Rectangular Motion Sensor Trash Can, Brushed Stainless...

- Premium Motion Sensor Technology - Experience the smoothest, most seamless lid opening and closing technology with this EKO hands-free automatic trash...

- Ultimate Fingerprint Resistance - Say goodbye to smudges and hello to a clean flawless exterior that stays immaculate. The anti-fingerprint stainless...

- Sleek and Durable Finish - Meticulously crafted with a stainless steel finish, this stylish touchless trash can offers a cool and smooth texture...

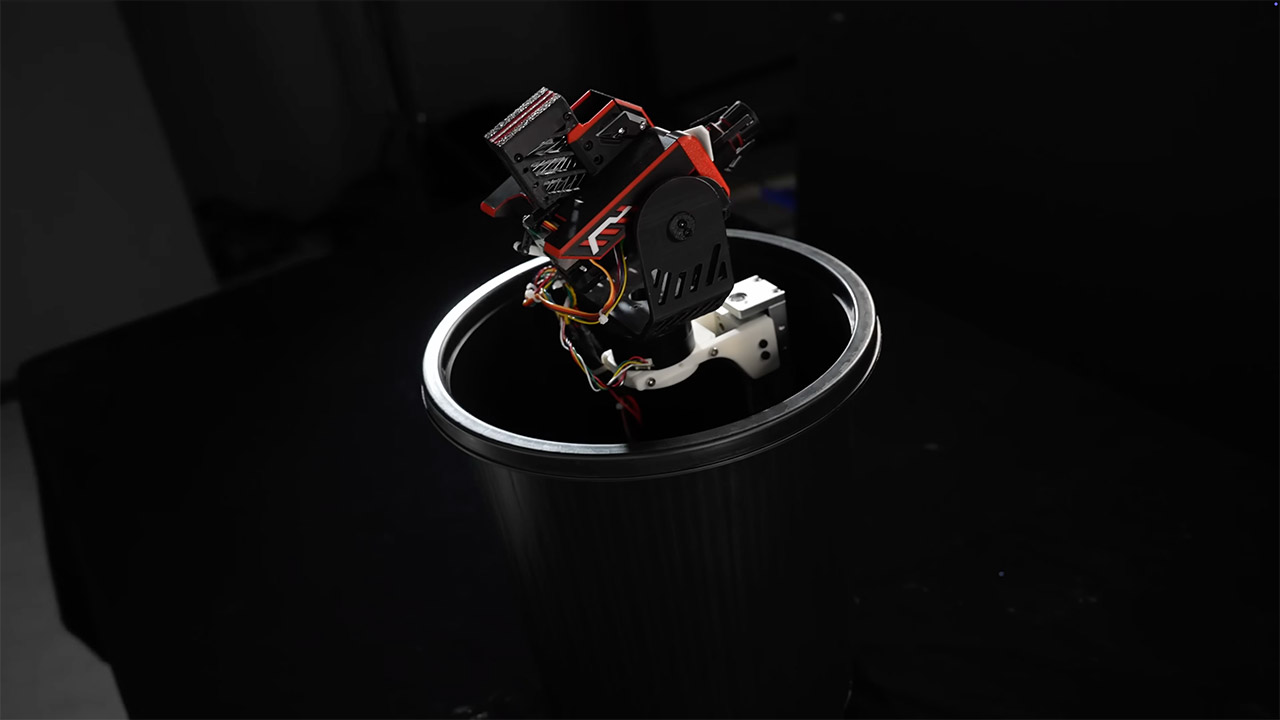

Each bin has a camera to detect airborne trash, a step beyond a 2013 project that used a fixed Kinect sensor. By putting the camera on the bin, HTX made it mobile. Engineers trained a model to recognize common items—paper balls, plastic bottles, food wrappers—and calculate their paths. Three high powered motors and wheels propel the bin to intercept trash before it hits the floor. A video of the first success is triumphant, with a paper ball landing in the speeding bin.

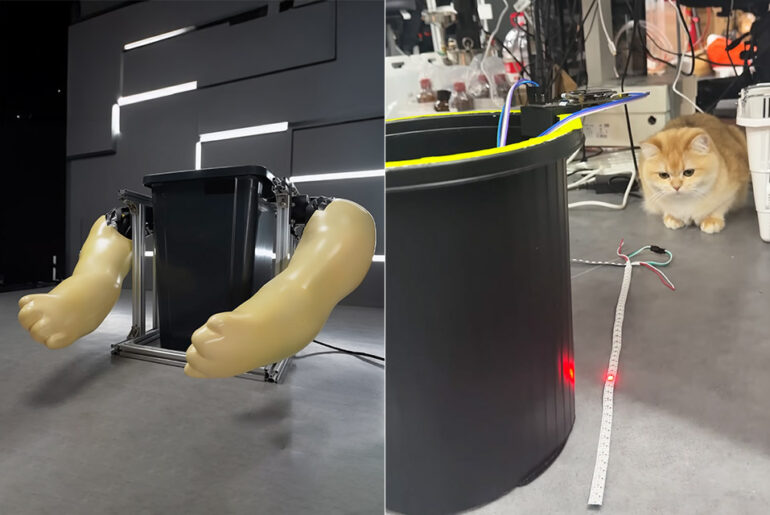

HTX made three different bins, each with its own flair. One is a floor-mopping cleaner and has a display for playing rock-paper-scissors, a fun twist. Another has a lid and a voice and taunts users with phrases like, “If you make it in, I’ll eat my lid!” The third, the Punishment Bin, ups the ante: miss a shot and it might fire a soft dart or, with a laser pointer swap, become a cat toy. All three bins can be controlled with one remote and parade together like a robotic trash can squadron.

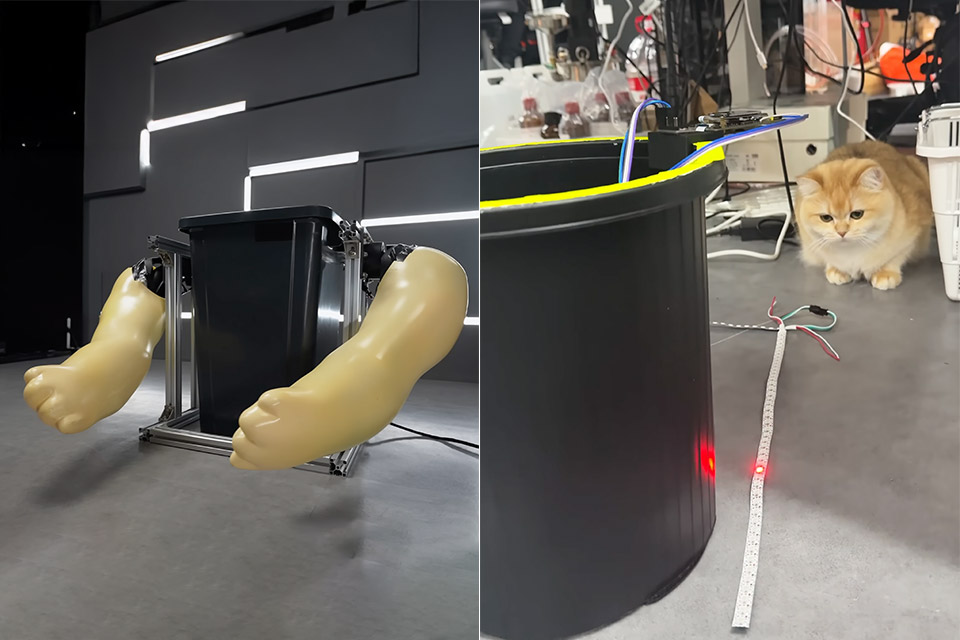

Emptying the bins required innovation. HTX developed a heat-seal mega bin that automates the process: small bins approach and a clamp lifts their bag system, seals the full bag with heated wires, cuts it off and drops it into the mega bin as a new bag takes its place. LED strips on the studio’s black floor guide the bins, with downward facing cameras following the glowing trails, especially cool in the dark when the studio feels “haunted” as the team calls it.

That required some cleverness. A rotating charging hub with magnetic contacts allows the bins to charge in sequence, no more battery swaps. The integration of cameras, motors, LEDs and chargers is HTX’s specialty.

[Source]