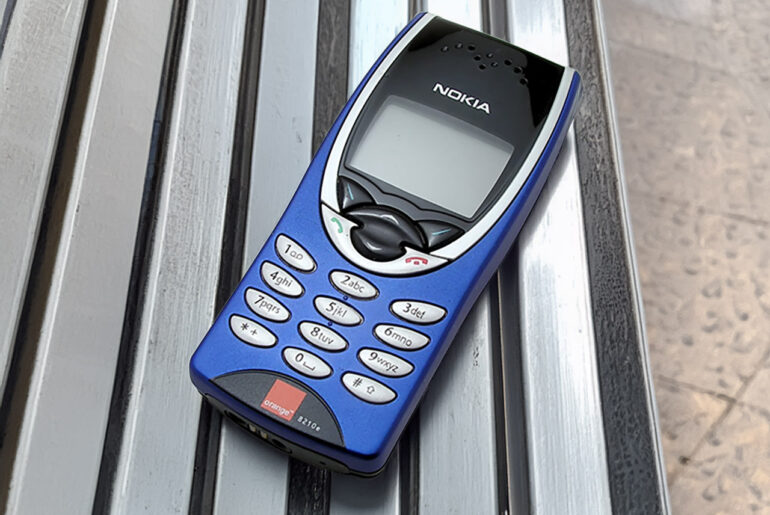

In 1999, Nokia was *the* mobile phone giant, and the Nokia 3210, a candy bar phone, was one of the most iconic. Its reputation for being indestructible – stories of surviving crashes, spills and even a car accident – was legendary. But how did Nokia make these almost mythical devices? A rare 1999 factory tour shows the process that produced the 3210 (and 8210).

Assembly started with the heart of the phone: the printed circuit board (PCB). Workers loaded blank boards into machines that placed tiny components – resistors, capacitors and chips – with pinpoint accuracy. These surface-mount technology (SMT) machines, guided by computer programs, could place thousands of parts per hour. Cameras and sensors scanned each board, flagging imperfections smaller than a grain of sand.

- NEW built-in stylus. Jot notes, edit photos, sketch artwork, and navigate effortlessly with an improved stylus and updated software.

- 6.7" pOLED display and Dolby Atmos. Experience cinema-quality entertainment with over a billion shades of color and multidimensional sound*.

- 50MP Ultra Pixel camera + OIS. Capture sharper low-light photos and smoother videos with an unshakable camera system featuring Optical Image...

Once the PCBs were populated, they moved onto the soldering stage. A wave soldering machine bathed the boards in molten solder, securing the components in place. Workers monitored the temperature and flow to prevent defects.

Injection-molded plastic casings, made in another part of the factory, arrived in stacks of colors. The 3210’s customizable face plates, a hit with younger users, were a key feature. The internal antenna, a first for mass-market phones, was carefully integrated, eliminating the fragile external stubs of earlier models.

Keypads, made of silicone rubber, were pressed in by hand to ensure each button had the satisfying click that 3210 users would become addicted to. The monochrome LCD screens, small by today’s standards but state of the art in 1999, were installed. These screens, capable of showing five lines of text, were tested for clarity and responsiveness. A single dead pixel would send a unit back for rework, a sign of Nokia’s zero tolerance for defects.

Workers connected each phone to a computer via a special cable and flashed the Series 20 UI onto the device. This software was basic but easy to use and powered the phone’s features: T9 predictive text, Snake game and custom ringtones via Nokia’s Composer. Testing rigs sent texts and made calls to test the software.

The removable 1,250 mAh NiMH battery was then slotted in. These batteries were a marvel of the time, giving days of standby and hours of talk time. The final assembly step was to attach the back cover, and then each unit was powered on for a final test, to check button responsiveness as well as speaker clarity.